ONTARIO – Representatives of

Castle Silver Resources of Coquitlam, B.C., have just returned from Asia where it hopes to find customers for its cobalt product produced with its proprietary Re-2OX process. The process is designed to meet the cobalt hydroxide specifications of four Japanese metal trading companies.

[caption id="attachment_1003719334" align="alignright" width="300"]

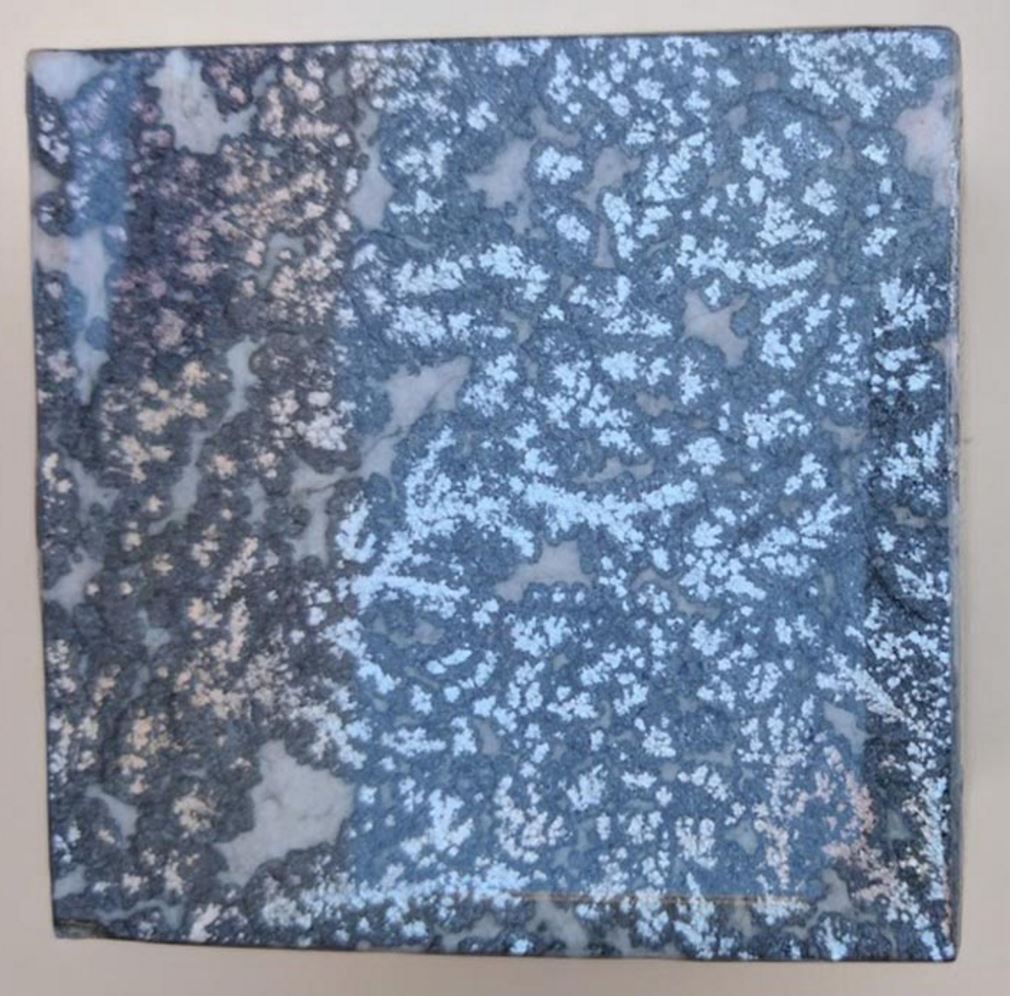

Cut surface of a quartz-carbonate vein with high grade silver (reflective) and cobalt mineralization (darker grey). (Credit: Castle Silver Resources)

Cut surface of a quartz-carbonate vein with high grade silver (reflective) and cobalt mineralization (darker grey). (Credit: Castle Silver Resources)[/caption]

SGS Lakefield has prepared a sample of 14.8% cobalt concentrate from material collected from the first level of the former Castle silver-cobalt-gold mine at Gowganda. The had an initial grade of 1.48% cobalt, 5.7 g/t gold, and 46.3 g/t silver. The concentrate will now be treated using the Re-2OX process.

Meanwhile, Castle Silver continues to explore the Castle property, a high grade past silver producer. Geologists interpret the shallow-dipping, 300-metre thick Nipissing diabase intrusive that underlies a large portion of the Castle property as a heat source that mobilized various metals, most importantly silver intimately associated with cobalt.

Additional information is available at

www.CastleSilverResources.com.

Cut surface of a quartz-carbonate vein with high grade silver (reflective) and cobalt mineralization (darker grey). (Credit: Castle Silver Resources)[/caption]

SGS Lakefield has prepared a sample of 14.8% cobalt concentrate from material collected from the first level of the former Castle silver-cobalt-gold mine at Gowganda. The had an initial grade of 1.48% cobalt, 5.7 g/t gold, and 46.3 g/t silver. The concentrate will now be treated using the Re-2OX process.

Meanwhile, Castle Silver continues to explore the Castle property, a high grade past silver producer. Geologists interpret the shallow-dipping, 300-metre thick Nipissing diabase intrusive that underlies a large portion of the Castle property as a heat source that mobilized various metals, most importantly silver intimately associated with cobalt.

Additional information is available at

Cut surface of a quartz-carbonate vein with high grade silver (reflective) and cobalt mineralization (darker grey). (Credit: Castle Silver Resources)[/caption]

SGS Lakefield has prepared a sample of 14.8% cobalt concentrate from material collected from the first level of the former Castle silver-cobalt-gold mine at Gowganda. The had an initial grade of 1.48% cobalt, 5.7 g/t gold, and 46.3 g/t silver. The concentrate will now be treated using the Re-2OX process.

Meanwhile, Castle Silver continues to explore the Castle property, a high grade past silver producer. Geologists interpret the shallow-dipping, 300-metre thick Nipissing diabase intrusive that underlies a large portion of the Castle property as a heat source that mobilized various metals, most importantly silver intimately associated with cobalt.

Additional information is available at

Comments