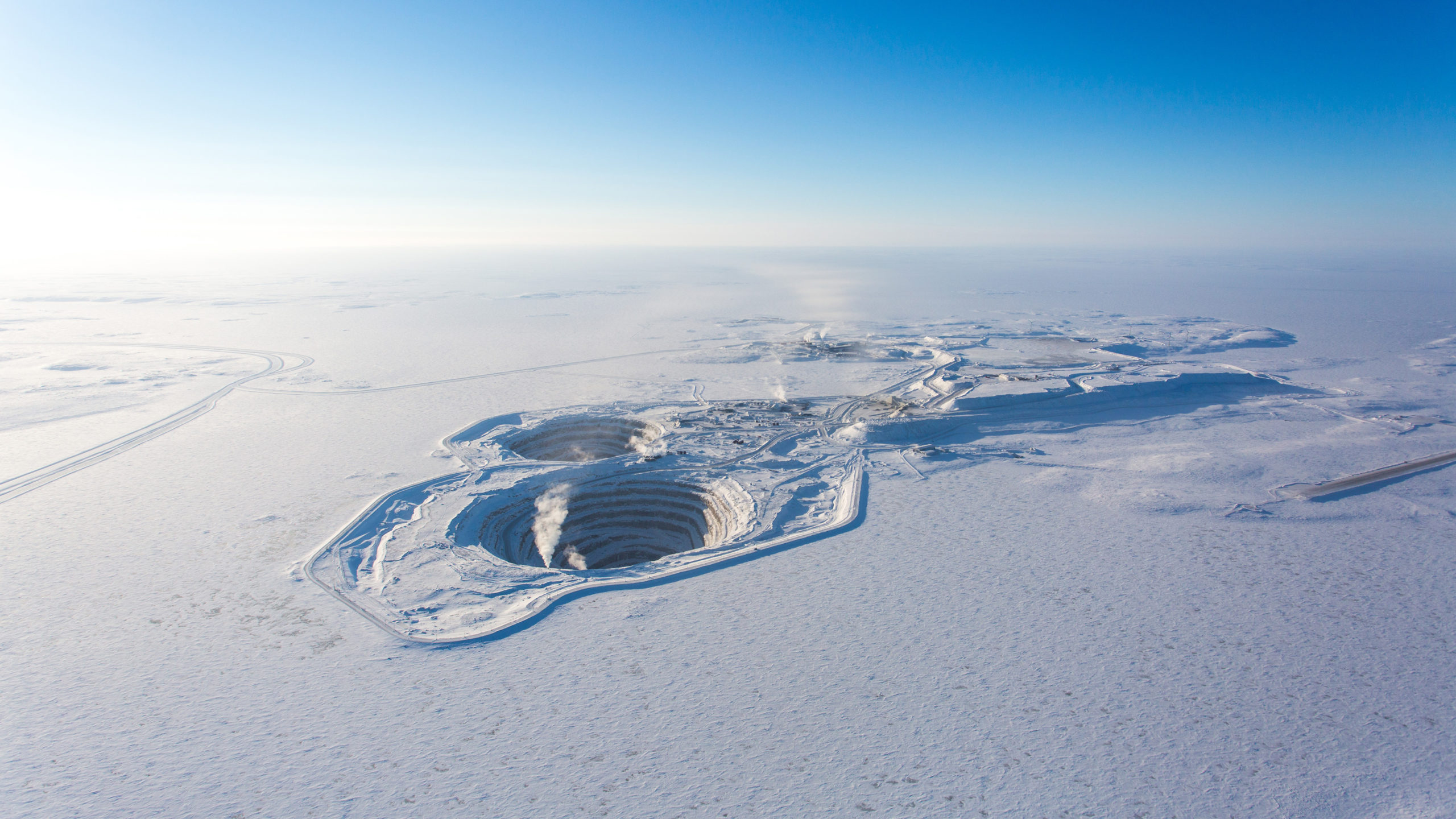

VANCOUVER – Micromine has completed stage one of the Pitram automated data collection project at the Diavik underground diamond mine at Lac de Gras.

The primary objective of the project is to accurately monitor the loading cycle of underground haul trucks. The project will also improve communication between haul truck operators and the Pitram control room, and ensure that the load tonnage captured by weight cell system LoadMan® is accurately reported in Pitram. Through improved communication and reporting capabilities, Diavik will increase productivity, reduce costs and improve safety.

In stage one of the project, Diavik added automated data capture capabilities to its existing Pitram solution, and integrated Pitram with LoadMan weight meters on selected trucks. Stage two will see Pitram's automated data capture capabilities extended across the entire hauling fleet during the second half of 2013.

Pitram is a leading mine control and management reporting solution which records, manages and processes mine site data in real-time related to equipment, locations, personnel and materials. Pitram provides key personnel with an overall view of mining operations.

Pitram system specialist for North America, Josh Carroll, explained, "Pitram was first implemented at Diavik in 2007. Over the years the solution has helped the site to accurately record mine activities, and has provided management greater control over the operation. Prior to the project's commencement, all underground information was communicated by operators to the Pitram control room over the radio. Although effective, management recognized that communication could be further improved."

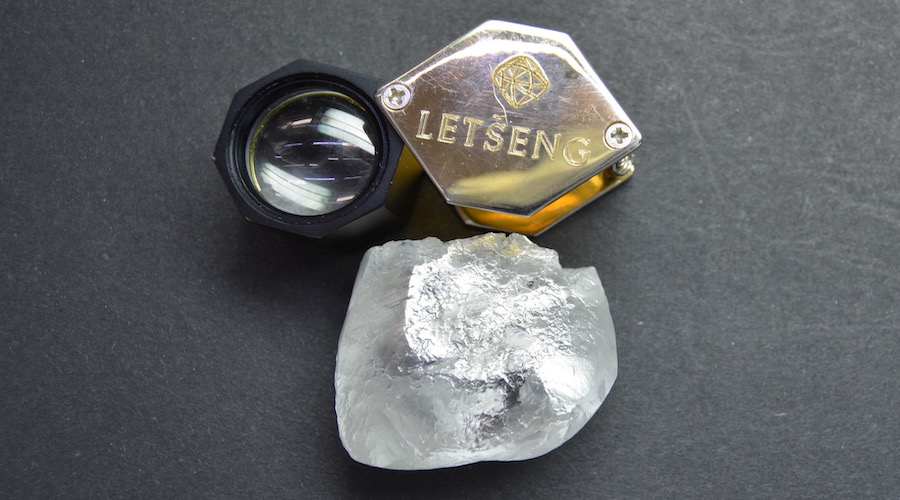

As part of that improvement process, and to better monitor and strengthen the consistency of the loading and hauling process, Diavik commissioned a weight cell system to be added to its hauling fleet. The system, LoadMan, allows the weight of material on a truck to be captured at the start and end of the load-dump cycle.

Carroll adds, "Pitram touchscreen computer units have been installed in four truck cabins, and integrated with LoadMan. An accurate tonnage measure of each truck dump is now displayed on the Pitram computer unit once the data has been captured by LoadMan. The information is then made available to key personnel through Pitram's reports."

All common Pitram events entered into the computer – including location and loader assignments, status (time model) changes, and cycle status changes – are communicated to the control room when trucks pass wireless access points.

Micromine's Pitram staff remained onsite throughout the implementation to ensure Diavik's administrators and dispatch operators were fully supported and trained on how to use the new system. Since the completion of stage one, Micromine has provided offsite support.

Micromine (Micromine.com) has recently deployed similar projects within a number of other sites, including Newmont's Leeville and Midas mines in Elko, Nevada, and the Kinross Kupol mine in Russia. Most significantly, three automated Pitram solutions have now been deployed within North America, ensuring that operations within the region are utilizing the most sophisticated mine control and management reporting technology available.

Comments