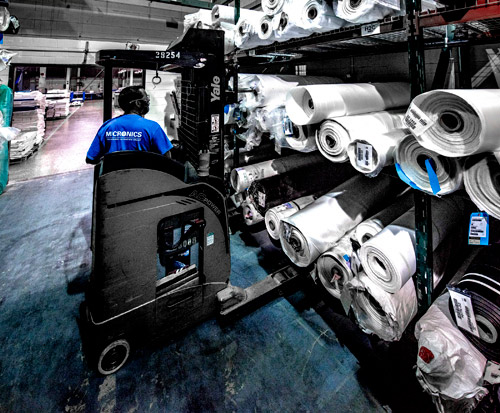

[caption id="attachment_1003740236" align="aligncenter" width="500"]

Filter cloth inventory Credit: Micronics

Filter cloth inventory Credit: Micronics[/caption]

NEW HAMPSHIRE - The

Micronics Engineered Filtration Group has introduced its newest filter press cloth product, the Mine-XLL filter cloth. This filtration offering was developed specifically for the mining industry to provide a long-life solution, with fewer filter cloth change-outs, which can be a pain point in the dewatering stage of the processing cycle.

According to Micronics, typical mining filter cloths in mineral processing feature a lifetime of approximately 1,500 cycles to 3,000 cycles. Micronics’ new Mine-XLL typically achieves a lifetime that is up to three times higher when compared with traditional polypropylene (PP) felted mining cloths.

The new mining cloth has been tested and evaluated at 10 mine sites with performance exceeding expectations - some mines have achieved over 10,000 cycles before needing to change out the cloth.

Micronics’ new heavyweight nylon filter press cloth also allows for an easier cake release when compared with traditional PP felted mining cloth, with greater mechanical resistance to abrasive, high-velocity mine slurries and lower cake moistures for lower hauling costs.

“We are very pleased to hear the reactions of our customers to the cost savings from using our new product. Using Micronics’ new Mine-XLL filter cloth, there is more press up-time and we estimate that clients can experience well over US$100,000 per year in cost savings, both through labour and productivity improvements and lower hauling costs,” Chris Cummins, president and CEO of Micronics, said in a release.

“From the initial start of testing, our moistures ran and averaged 10%, and since installation of the new mining cloth, we are now averaging 7.4%. This is a huge savings when you talk about transportation costs,” added a process manager in the milling department of a North American copper mining company.

Micronics’ Mine-XLL filter cloth can be manufactured to fit all OEM (original equipment manufacturer) brands of mining filter presses on the market today.

Micronics is a worldwide expert in liquid-solid separation. Incorporated in 1983, Micronics has been a portfolio company of Vance Street Capital, a Los Angeles-based private equity firm, since 2013.

For more information, visit

www.MicronicsInc.com.

Filter cloth inventory Credit: Micronics[/caption]

NEW HAMPSHIRE - The Micronics Engineered Filtration Group has introduced its newest filter press cloth product, the Mine-XLL filter cloth. This filtration offering was developed specifically for the mining industry to provide a long-life solution, with fewer filter cloth change-outs, which can be a pain point in the dewatering stage of the processing cycle.

According to Micronics, typical mining filter cloths in mineral processing feature a lifetime of approximately 1,500 cycles to 3,000 cycles. Micronics’ new Mine-XLL typically achieves a lifetime that is up to three times higher when compared with traditional polypropylene (PP) felted mining cloths.

The new mining cloth has been tested and evaluated at 10 mine sites with performance exceeding expectations - some mines have achieved over 10,000 cycles before needing to change out the cloth.

Micronics’ new heavyweight nylon filter press cloth also allows for an easier cake release when compared with traditional PP felted mining cloth, with greater mechanical resistance to abrasive, high-velocity mine slurries and lower cake moistures for lower hauling costs.

“We are very pleased to hear the reactions of our customers to the cost savings from using our new product. Using Micronics’ new Mine-XLL filter cloth, there is more press up-time and we estimate that clients can experience well over US$100,000 per year in cost savings, both through labour and productivity improvements and lower hauling costs,” Chris Cummins, president and CEO of Micronics, said in a release.

“From the initial start of testing, our moistures ran and averaged 10%, and since installation of the new mining cloth, we are now averaging 7.4%. This is a huge savings when you talk about transportation costs,” added a process manager in the milling department of a North American copper mining company.

Micronics’ Mine-XLL filter cloth can be manufactured to fit all OEM (original equipment manufacturer) brands of mining filter presses on the market today.

Micronics is a worldwide expert in liquid-solid separation. Incorporated in 1983, Micronics has been a portfolio company of Vance Street Capital, a Los Angeles-based private equity firm, since 2013.

For more information, visit

Filter cloth inventory Credit: Micronics[/caption]

NEW HAMPSHIRE - The Micronics Engineered Filtration Group has introduced its newest filter press cloth product, the Mine-XLL filter cloth. This filtration offering was developed specifically for the mining industry to provide a long-life solution, with fewer filter cloth change-outs, which can be a pain point in the dewatering stage of the processing cycle.

According to Micronics, typical mining filter cloths in mineral processing feature a lifetime of approximately 1,500 cycles to 3,000 cycles. Micronics’ new Mine-XLL typically achieves a lifetime that is up to three times higher when compared with traditional polypropylene (PP) felted mining cloths.

The new mining cloth has been tested and evaluated at 10 mine sites with performance exceeding expectations - some mines have achieved over 10,000 cycles before needing to change out the cloth.

Micronics’ new heavyweight nylon filter press cloth also allows for an easier cake release when compared with traditional PP felted mining cloth, with greater mechanical resistance to abrasive, high-velocity mine slurries and lower cake moistures for lower hauling costs.

“We are very pleased to hear the reactions of our customers to the cost savings from using our new product. Using Micronics’ new Mine-XLL filter cloth, there is more press up-time and we estimate that clients can experience well over US$100,000 per year in cost savings, both through labour and productivity improvements and lower hauling costs,” Chris Cummins, president and CEO of Micronics, said in a release.

“From the initial start of testing, our moistures ran and averaged 10%, and since installation of the new mining cloth, we are now averaging 7.4%. This is a huge savings when you talk about transportation costs,” added a process manager in the milling department of a North American copper mining company.

Micronics’ Mine-XLL filter cloth can be manufactured to fit all OEM (original equipment manufacturer) brands of mining filter presses on the market today.

Micronics is a worldwide expert in liquid-solid separation. Incorporated in 1983, Micronics has been a portfolio company of Vance Street Capital, a Los Angeles-based private equity firm, since 2013.

For more information, visit

Comments