Conveyor safety and the return on prevention

Protecting workers should be the top priority for any employer, especially those on the front line of materials processing. Beyond the substantial financial consequences of a workplace injury or fatality, the impacts are felt profoundly by an employee’s family, their coworkers, and the wider community.

Thus, investing in safe, well-engineered equipment and prevention-focused training that helps protect workers from injury or illness is essentially investing in people, company culture, and the community. Martin Engineering’s technicians are increasingly applying their expertise to help operators control maintenance risks by sharing their knowledge and installing equipment that improves safety.

Although return on investment (ROI) is a common calculation when installing new conveyor accessories, some safety experts emphasize the return on prevention (ROP). This long-term strategy prioritizes equipment with safety engineered into the design, allowing for more ergonomic servicing, faster and easier access, and other improvements that make maintenance less dangerous and more desirable to do. Although safer equipment is typically a larger initial capital investment, the whole life return is in faster maintenance with less downtime, longer equipment life, and, importantly, a considerably lower chance of an incident, reducing the overall cost of operation.

The real costs of ROI

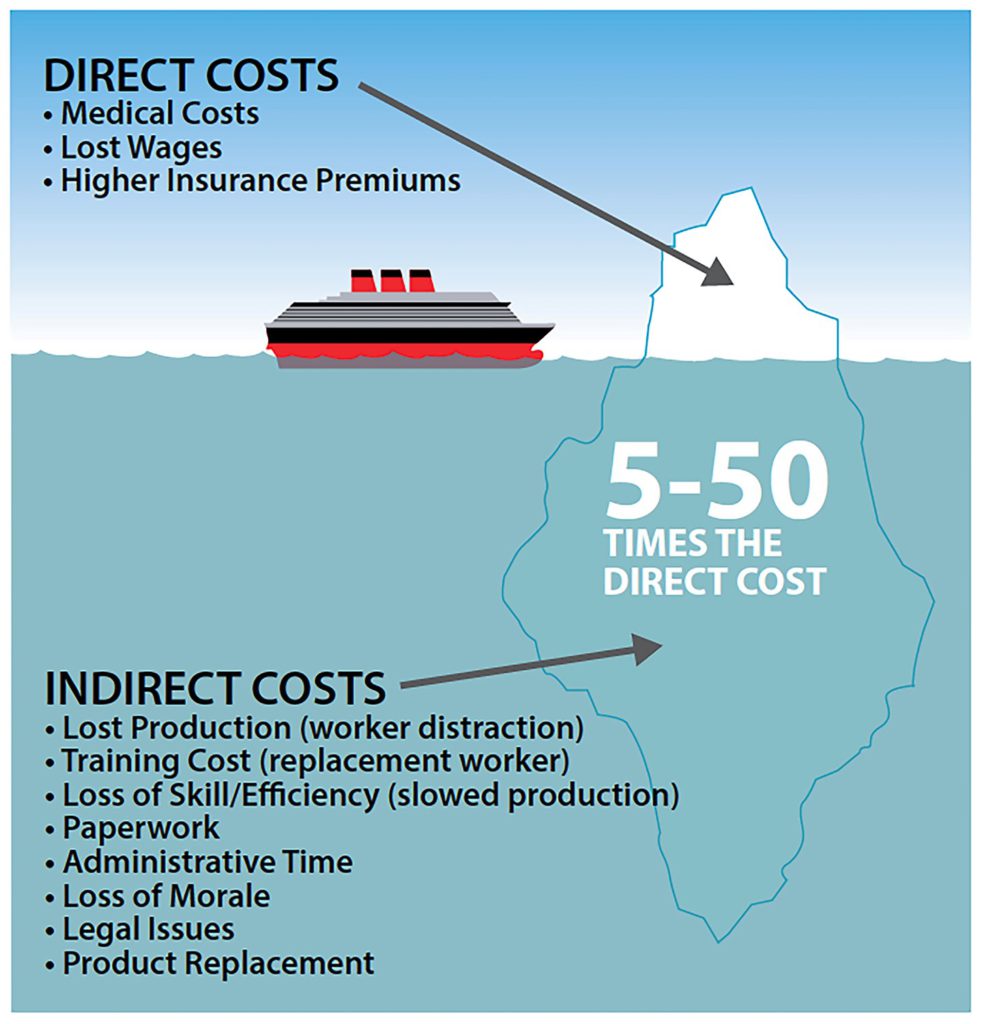

Calculating ROI on conveyor safety is specific to each operation, but in general, they can be broken down into “direct costs” and “indirect costs.”

Direct costs are explicitly associated with an accident or illness. In general, these include fines, medical bills, insurance premiums, indemnity payments, and temporary disability payments.

Indirect costs include a variety of other expenses resulting from the incident. These include the following:

- Cleanup time and product loss.

- Equipment repair/replacement.

- Purchase/installation of safety components.

- Overtime to fill in for the missing worker.

- Cost of hiring, training, and equipping new employees.

- Legal fees and litigation costs.

- Increased insurance premiums.

- Production delays and missed shipment targets.

- Reduced employee morale and greater absenteeism.

- Negative publicity.

- Increased scrutiny by regulators.

The price of recovering from an accident

To demonstrate the benefits of safety to a company’s bottom line, the Occupational Safety and Health Administration (OSHA) in the U.S. created the online tool, “$afety Pays,” which uses company-specific economic information to assess the potential economic impact of occupational injuries on that firm’s profitability. The program estimates direct costs (claim cost estimates provided by the National Council on Compensation Insurance) and indirect costs (provided by the Stanford University Department of Civil Engineering) and weighs them against financial details supplied by the company.

Return on prevention (ROP)

The commonly used ROI model calculates the time frame in which the capital expenditure on new equipment is recaptured through the improvements. If a proposed project meets budget expectations and has a payback period of less than one year, plant management usually approves it.

Working with abstract numbers implicitly creates pushback, making it more difficult for safety-conscious managers to obtain approval for their proposals. However, the hard costs of worker injuries and fatalities are very real. The ROP model illustrates the direction and strength of occupational safety and health programs in helping to achieve company goals.

Conclusion

The death or serious injury of a worker is always tragic and can have long-term impacts for all those involved. Investigations usually reveal that incidents could have been prevented with the right knowledge and behaviours, combined with practical and cost-effective safety improvements. The ROP on durable, well-designed conveyor accessories and professional training makes good financial sense and can lead to a safety culture that ripples throughout the company’s balance sheet.

Jerad Heitzler is training manager at Martin Engineering.

Comments