Optimizing the performance of tailings thickeners

Water scarcity and climate risk have become central concerns in the mining industry over the past decade. This is especially true in regions like Chile, Peru, Indonesia, and parts of Africa, where severe drought conditions are creating significant environmental challenges. Copper and lithium mining have been identified as contributors to groundwater depletion and ecosystem disruption. Industry experts warn that nearly one-third of global semiconductor production relies on copper sourced from areas projected to be water-stressed by 2035.

In Peru and Indonesia, local communities have reported drying water sources, contaminated supplies, crop failures, and health issues, many of which are tied to mining water use and pollution. In response, water recovery and tailings reclamation have emerged as essential components of responsible mining practices. Mining companies, stakeholders, and sustainability researchers are increasingly focused on innovative solutions that both recover water used in mining processes and restore land impacted by tailings and mineral extraction.

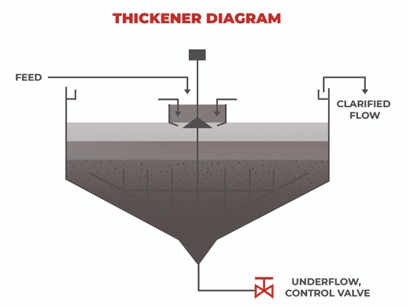

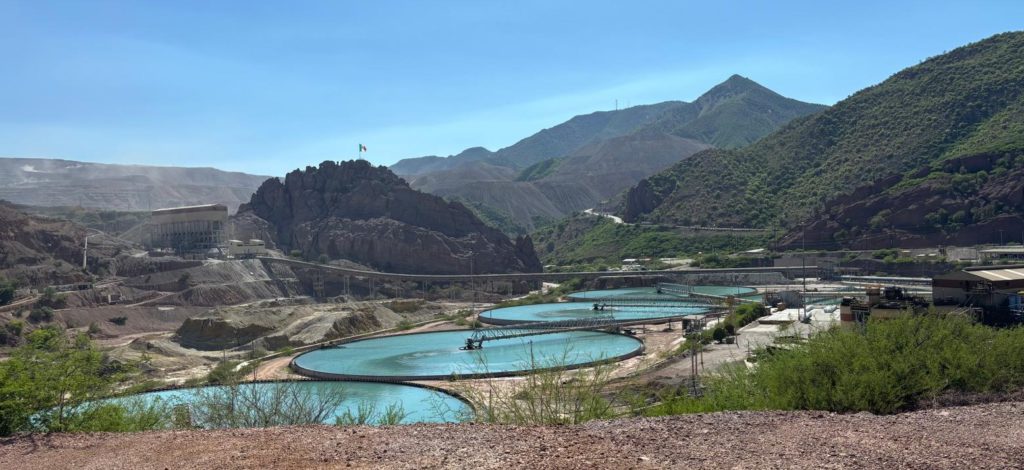

One of the most widely adopted technologies in water recovery and tailings management is the tailings thickener. These large, cylindrical tanks are designed to concentrate tailings slurry by reducing its water content. Through gravity sedimentation, thickeners allow water to be recovered and reused in processing, while the solids are collected and prepared for safe disposal.

A conventional thickener operates on the principle of gravity, typically using slow raking to settle and compact solids. High-rate thickeners (HRTs), on the other hand, incorporate optimized feedwell designs and flocculant chemistry to accelerate the settling process. While different thickener types are suited to different applications, the operational challenges they face are similar. These challenges not only affect water recovery and tailings management but can also lead to high operational costs, and in some cases, health and safety hazards for operators.

Common thickener challenges

Among the most common challenges are rake torque overload, which can occur if solids do not settle evenly; flocculant inefficiency, where poor mixing leads to the carryover of solids in the overflow; blockages, towing to issues with the underflow discharge or rake mechanism; and complete system shutdowns, caused by premature wear on the main underflow level control device. This latter challenge is a persistent operational problem that many mines across the world face daily, and the losses in process water recovery are countless.

These problems are especially critical when it comes to the underflow level control device, a key component in maintaining proper thickener operation. In many mines around the world, underflow device failure is a daily reality. The losses in water recovery caused by these failures are often substantial.

The role of technology in addressing wear and control

While progress has been made in areas like smart sensors, automation, and improved flocculant chemistry, controlling the thickener underflow remains one of the most difficult challenges in mining fluid control. Thickeners are among the most abrasive applications in the industry, and unfortunately, many of the valves and orifice plates used in these systems were never designed for such demanding conditions.

Most traditional control devices are standard valves originally developed for clean service or much lower solids concentrations. However, thickener underflow often contains 55% to 80% solids by weight and slurries with viscosities up to 5000 mPa·s. In such extreme conditions, improper discharge control not only leads to accelerated equipment failure but also to critical water losses.

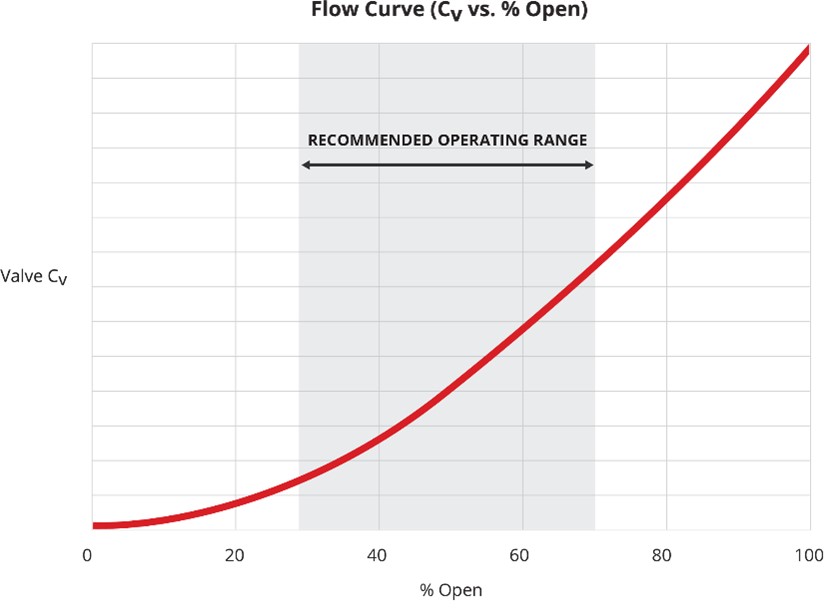

More attention is now being given to the custom design of discharge control devices tailored specifically to thickener applications. The challenge is twofold: not only must these devices withstand extreme abrasion, but they must also offer a wide range of controllability. In the event of overflow, caused by environmental or operational factors, the control device must allow for enough flow capacity to prevent choking while still maintaining control over the tailings level.

In many current installations, mines resort to manually swapping fixed orifice plates, a stopgap measure that lacks responsiveness and leads to operational inefficiencies. For example, sometimes no control valve is used in the underflow piping system of a thickener because none have lasted longer than 10 hours in operation. Certain applications include high quartz content, contributing to extreme abrasiveness, and relies instead on a manual level control system with fixed orifices. This method not only raises operational costs but is highly inefficient in terms of water recovery, ultimately increasing the mine’s water consumption.

A new approach: Custom-made control valves for abrasive slurries

A technology that has proven successful in these environments involves the use of custom-engineered control valves specifically designed for abrasive slurry applications. These valves offer a flow characteristic (e.g., equal percentage) aligned with the requirements of thickener applications. This approach centers the flow path and ensures that only replaceable components are exposed to abrasive media.

This solution involves a custom orifice plate, designed to meet the full range of required flow conditions. The plate is integrated into a specially designed knife gate valve shell, with a customized gate that allows for controlled variability across the flow range.

Real-world results

The use of these custom designed valves for thickener level control has shown significant benefits over conventional methods. Mines adopting these solutions have reported a 95% reduction in shutdowns owing to underflow valve failures, resulting in marked improvements in process efficiency and water recovery.

Tailings thickeners play a critical role in the sustainable operation of modern mines. As water scarcity continues to pressure the industry, optimizing thickener performance, particularly at the underflow control level, is not just an operational priority but an environmental necessity. The development of application-specific control technologies is helping mines around the world improve water recovery, reduce downtime, and meet their sustainability goals more effectively.

Amir Emami, P.Eng., is a mechanical engineer and the current vice president of engineering at Special Alloy Fabricators (SAF). He has 14 years of experience in valve design, flow analysis, and product development. Over the past nine years, he has been leading a growing engineering team at SAF with a dedicated approach in custom designing flow equipment for some of the most challenging applications around the world.

Maria Aguirre, P.Eng., M.Eng., is a mechanical engineer and current business development manager at Special Alloy Fabricators (SAF), she holds a master’s degree in engineering and has 14 years of experience in the valve and automation industry.

Comments