Solving the puzzle: Overcoming the barriers to ventilation-on-demand in underground mining

Underground mining has long been a balancing act between productivity, safety, and cost. As operations go deeper and get more complex, the need for smarter, more responsive systems has never been greater. One of the most promising innovations is Ventilation-on-Demand (VoD) — a strategy that dynamically adjusts airflow based on real-time conditions, rather than relying on fixed schedules or manual overrides.

The advantages of VoD are widely reported: reduced energy use, improved air quality, enhanced safety for workers, and lower operational costs. Despite its promise, VoD is still not widely used in the global mining sector. The question is no longer whether VoD is effective — it is why it is not the norm.

The solution is in a set of persistent, interconnected issues: communication infrastructure, sensor reliability, and precise tracking of both personnel and equipment. These are not merely technical challenges but systemic barriers that need to be addressed in an integrated manner.

1. The communication network puzzle

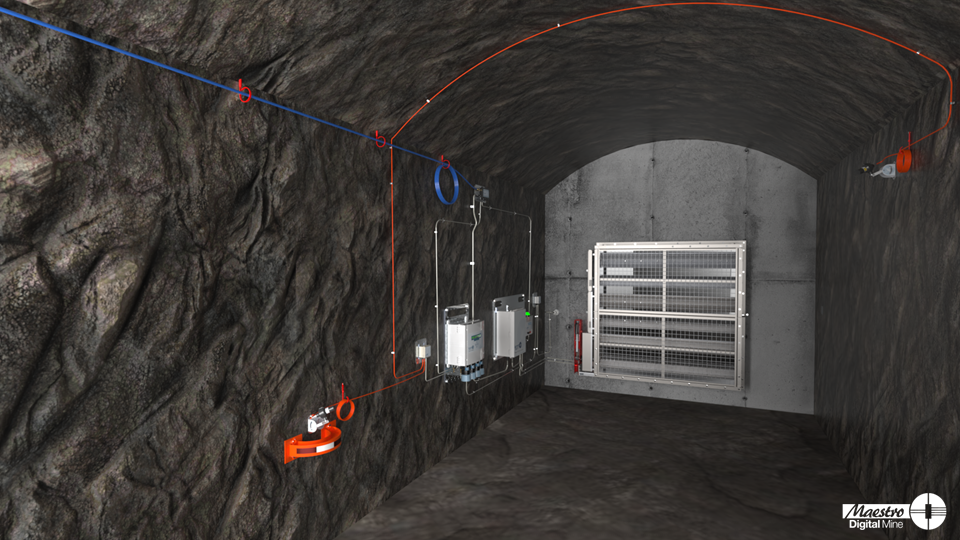

At the heart of any VoD system is the ability to transmit data reliably and in real time. Underground mines, however, provide one of the most challenging environments in which to have digital communication. Drifts turn and loop, rock walls absorb or scatter signals, and electromechanical equipment generate signal interference. Add in perpetual dust, water, vibration, and harsh temperatures, and it is no wonder most mines still have outdated or patchwork communications systems.

Without a robust network, VoD systems are essentially blind. Sensors cannot report their readings, control systems cannot respond, and operators are left to make decisions based on incomplete, outdated, or even delayed information. Even momentary loss of sensor connectivity can lead to over-ventilation, wasted energy, or worse: missed warnings of hazardous conditions.

The ideal network for VoD must be strong, expandable, and low maintenance. It must be able to support high-bandwidth information, enable device plug-and-play integration, and support operation by mine personnel without IT specialist expertise. But most importantly, it must be specifically developed for underground use — rather than a surface-based technology derivative.

2. Reliability of sensors in harsh environments

VoD depends on a cluster of field sensors to monitor airflow, gas concentrations, temperature, humidity, and other environmental conditions in the surroundings. Sensors are the eyes and ears of the system, providing data that drives ventilation decisions. But underground, sensors face relentless abuse.

Corrosive gases, mechanical shock, water penetration, and extreme temperature swings can degrade sensor performance or cause outright failure. When sensors provide inaccurate readings — or fail to provide readings at all — the consequences can be serious. Ventilation systems may overcompensate, wasting energy, or underperform, putting workers in danger.

Reliability is not just about ruggedized hardware, it is a question of diagnostics, calibration, and redundancy, as well. Sensors need to be able to detect when they are drifting out of spec, alert operators for maintenance, and continue to operate even if part of the system goes down. Mines need confidence in the reliability of their information, especially when lives and regulatory compliance are involved.

Furthermore, sensors should be easy to install and maintain. In many cases, the teams maintaining the systems are not the instrumentation specialists, they are electricians, mechanics, or ventilation technicians. A VoD system that demands constant attention from specialists will not be feasible.

3. Following the movement that matters

The third fundamental component of VoD is having real-time awareness of equipment and individuals. Ventilation demands vary wildly depending on activity and occupancy. An empty stope may require minimal air, but an active heading requires full air.

Without accurate monitoring, VoD is guesswork. Mines may ventilate areas unnecessarily, wasting energy, or fail to ventilate occupied areas sufficiently, threatening safety. Normal procedures — manual logs, radio check-ins, or periodic ventilation — are no longer sufficient.

Current tracking systems utilize RFID, Bluetooth, Wi-Fi, and UWB technologies to track people and equipment mobility. But these need to be closely integrated with environmental monitoring and control systems. Simply knowing a person’s location is not enough — the system needs to be able to link that position to air quality information and react accordingly.

The interconnected nature of the challenge

What makes these three challenges particularly difficult is their interdependence. A reliable sensor may not operate without a network. A tracking system cannot influence ventilation decisions without integration. And a robust network is only valuable if it supports the right devices and data stream.

This interconnectivity does not allow for a VoD solution being piecemealed. Mines must approach it at the systems level, investing in platforms that unify data, provide ease of deployment, and enable real-time decision-making. It is not just automation — it is environmental intelligence.

Environmental intelligence goes beyond raw data. It is about understanding patterns, predicting needs, and responding proactively. It is making the underground mine a living system — one that breathes, adapts, and protects its people.

The path forward

The mining sector stands at a crossroad. The technology for VoD is available. The advantages are obvious. Now, what is required is a change of mindset — from reactive to proactive, data-driven operations.

This change requires leadership, investment, and collaboration. It requires suppliers who understand the underground environment, and technologies designed to the realities of mining — not just the theories of automation. It requires modular, interoperable, and scalable systems, so that mines can start small and grow over time.

Most importantly, it requires trust. Operators must trust their data, their systems, and their partners. It is earned through reliability, transparency, and results.

Putting the pieces together

Each of the barriers to VoD — communication, sensing, and tracking — represents a piece of a larger puzzle. Solving that puzzle requires more than just technology. It requires integration, insight, and a deep understanding of the underground mining environment.

Comments