Rotary kilns: Advancing critical mineral recovery

Canada, like many other nations, faces increasing pressure to establish a reliable supply of critical minerals, from nickel and lithium to graphite and rare earth elements (REEs).

And while potential sources abound, recovering these materials requires advanced processing solutions. With flexible capabilities, rotary kilns emerge as an essential tool in unlocking critical mineral recovery, from sources both new and old.

Growing demand for critical minerals

From defense systems to electric vehicle batteries, advancements in technology, along with a growing global population, continue to drive demand for critical minerals to ever greater heights.

With the push toward a circular economy, and most traditional mineral sources fraught with geopolitical challenges, mineral producers are exploring every potential resource for recovery, pushing the envelope into extracting materials from low-grade ores, industrial wastes, and post-consumer goods.

The complex makeup of these sources, as well as the wide range of forms in which they exist, often require advanced thermal processing techniques to unlock target components effectively and economically. And this is where rotary kilns excel.

Why rotary kilns

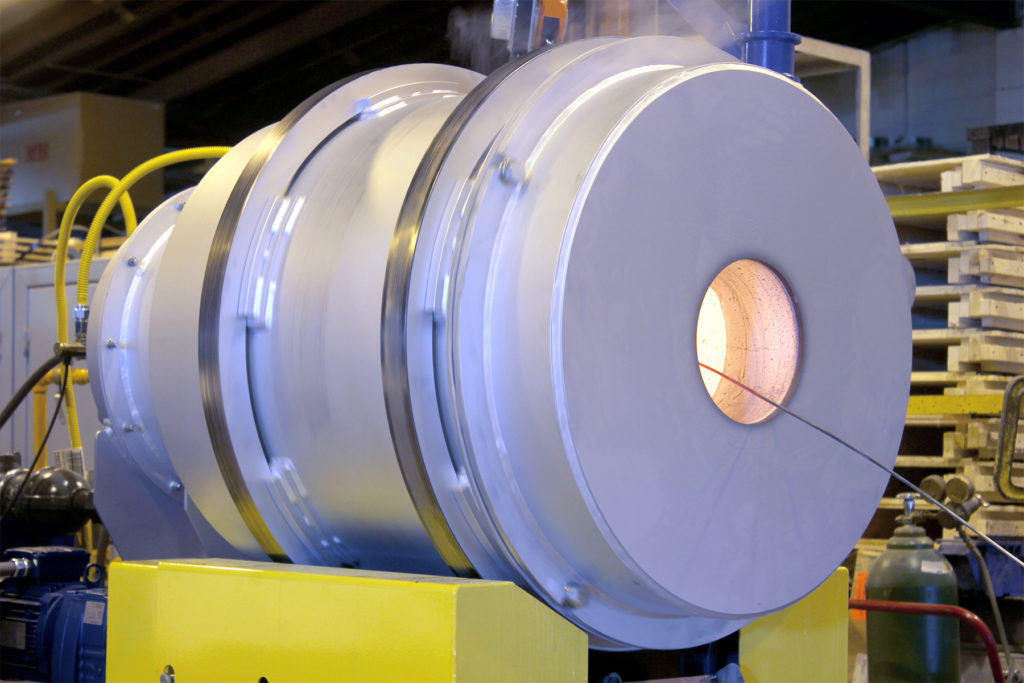

Rotary kilns are just one form of technology employed in the litany of techniques used to recover critical minerals. Their flexible thermal treatment capabilities, along with several other advantages, uniquely position them to accomplish a range of material-specific goals ranging from reduction to calcination.

Using high temperatures and controlled process environments, rotary kilns facilitate chemical reactions and phase changes. Depending on the configuration (direct or indirect), temperature control along the length of the kiln can be achieved for precise reaction management.

Applications in critical mineral recovery

Long proven in the cement industry, the rotary kiln’s high throughput, rugged build, and long-term reliability has led to this equipment being employed in a growing list of applications aimed at recovering critical minerals.

1) Lithium recovery from spodumene

While the industry has long relied on the extraction of lithium from brines because of its lower processing costs, extraction from spodumene, a lithium-rich ore found throughout Canada and the world, is making a comeback.

To extract lithium from spodumene, however, the spodumene must first be converted from alpha to beta phase, a process known as decrepitation. This is achieved through calcination in a rotary kiln, in which the ore’s crystal structure is shattered, making it amenable to downstream recovery.

2) Graphite and advanced carbon materials

In addition to lithium production, both natural and synthetic graphite production rely on the high-temperature processing capabilities of rotary kilns, which purify graphite, modify its structure, and prepare it for use in battery anodes.

Other advanced carbon materials are also produced through high-temperature treatment, including carbon black, activated carbon, and graphene, among others.

3) RREs from fly ash (and other materials)

Beyond traditional avenues to obtain essential minerals, rotary kilns are also vital in recovering them from secondary sources.

Fly ash, the coal ash remaining from coal-fired power generation stored in piles and ponds all over the content, is increasingly being explored for the potential value it holds in REEs.

A recent study coming out of the U.S. confirmed what many long suspected: the nation’s accessible coal ash piles are holding $8.4 billion worth of REEs. While a universal approach to commercial-scale extraction is still under investigation, rotary kilns offer the ideal customizable, controlled environment for calcining or roasting ash, a key step in unlocking rare earths from their mineral matrices.

4) Red mud

Like fly ash, red mud, or bauxite residue, is also a major industrial waste stream, one that has received growing attention in recent years because of the failure of large-scale storage ponds. Alkaline waste is produced in significant amounts during the conversion of bauxite to alumina in the production of aluminum via the Bayer process.

Red mud presents complex processing challenges, but can be rich in several important metals, such as iron, aluminum, titanium, REEs, and a host of others.

Not surprisingly, rotary kilns are under consideration for recovering these metals, particularly when it comes to iron; the hematite component in red mud can be converted to magnetite, allowing the iron to be magnetically separated.

5) Lithium-ion batteries

End-of-life lithium-ion batteries contain a mix of critical minerals as well, including lithium, cobalt, nickel, copper, and aluminum. And although there are challenges to overcome in scaling lithium-ion battery recycling, rotary kilns provide the controlled, high-temperature environment needed for recovering these components by eliminating the volatile organic compounds (VOCs) they are entrapped in.

Rotary kilns are also increasingly being used in the recovery of black mass from spent batteries. Black mass, an intermediate material produced in the process of breaking down batteries, is also rich in critical minerals.

6) Used beverage cans (UBCs)

Beyond the metals we have already covered, aluminum recovery also continues to advance, with used beverage cans (UBCs) and other aluminum scrap serving as essential sources of secondary aluminum.

Before aluminum can be effectively recovered, however, any coatings, oils, or lacquers affixed to the scrap must be chemically removed. This process, known as decoating or delacquering, is carried out in a rotary kiln, which uses thermal treatment to oxidize VOCs, leaving aluminum behind.

Decoating is especially valuable in maximizing aluminum recovery because it allows for a wider array of scrap types to be processed. Further, utilizing a decoating step helps to reduce metal losses during recycling and increases plant safety by eliminating any water that might be trapped in dirty scrap.

7) E-waste

In the same way rotary kilns remove VOCs from spent batteries and aluminum scrap, they can also oxidize the VOCs present in e-waste such as cellphone batteries, circuit boards, and the like — a category of waste that continues to grow in volume.

Rich in several metals, e-waste has long been recognized as a major “urban mining” opportunity.

8) Spent catalysts

Spent catalysts can also host a variety of critical minerals, including cobalt, vanadium, and nickel. Here again, a rotary kiln can be used to volatilize the organic compounds so the target metal(s) can be effectively separated from the catalyst support.

Challenges and considerations

Each mineral deposit and waste stream presents unique and often-unknown process and equipment requirements, making process development testing and custom rotary kilns essential.

Process development testing

Because critical mineral recovery is still in development for many feedstocks, pilot-scale testing in facilities such as the FEECO Innovation Center remains pivotal to developing commercial-scale solutions.

Process development testing in batch- and pilot-scale kilns aids producers in establishing and optimizing the process data needed to achieve their goals. Test rotary kilns can reveal key data points ranging from temperature profiles to retention time, kiln slope, speed, and more.

Custom rotary kilns

From the atmosphere inside the kiln to custom internals and inlet design, rotary kilns intended for critical mineral recovery will need to be engineered to meet the process and material demands of their intended application.

Additionally, given that many of these materials are caustic and abrasive, equipment will need to be designed and fabricated for longevity, despite challenging operating conditions.

Kiln design requirements are largely established through the types of testing procedures mentioned above but also rely on manufacturer expertise. Work with a reputable kiln supplier to ensure the design and construction account for process and material parameters, achieving an optimized process and long-term reliability.

Conclusion

As Canada accelerates its role in critical mineral development, rotary kilns are proving to be indispensable in making recovery possible. From spodumene conversion to REEs roasting and graphite purification, these advanced thermal treatment systems enable the physical and chemical transformations that turn resources into viable sources of supply.

For a nation seeking to lead in clean energy and advanced manufacturing, rotary kilns represent more than a piece of equipment; they are a bridge between raw potential and real-world supply.

Alex Ebben is a process sales engineer at FEECO International.

Comments