Metso slashes downtime with new gear

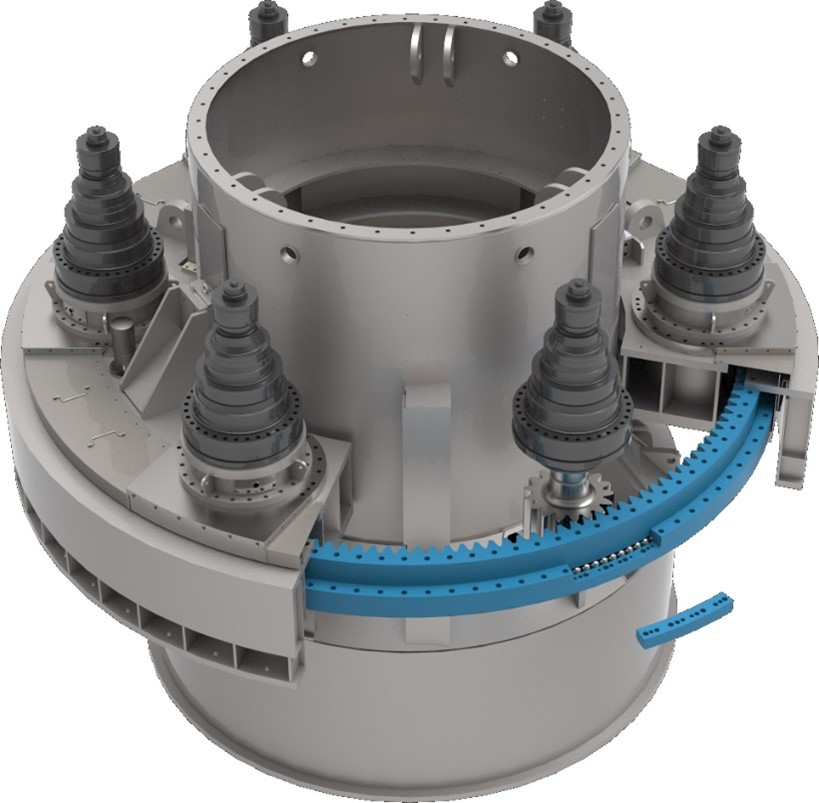

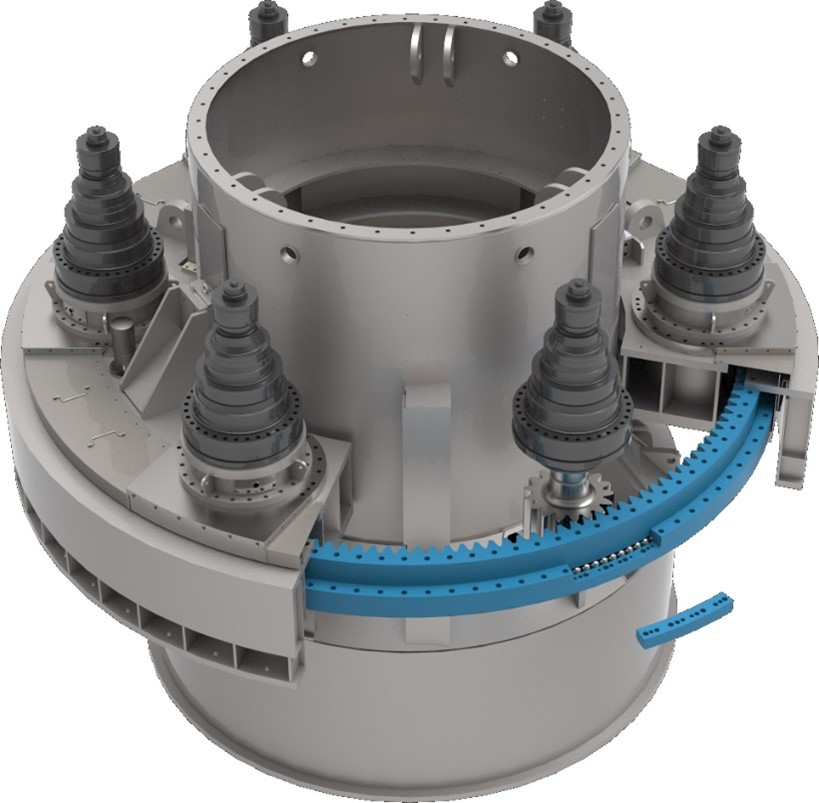

In a groundbreaking move, Metso unveiled its largest split geared ring model, the SCDH4500, on November 20, 2025. This innovative development marked a significant stride in revolutionizing thickener maintenance and underscored Metso's dedication to enhancing reliability, safety, and sustainability in mining operations.

The SCDH4500 tackled the practical issues associated with traditional full slew bearing replacements. Its unique two-piece split design allowed for quicker installation and reduced the need for extensive system disassembly. This approach minimized downtime and improved safety by eliminating the use of large cranes and suspended loads.

Metso's launch of the SCDH4500 aligned with its broader strategy to expand its thickener offerings and bolster its aftermarket capabilities. The new model integrated seamlessly with existing SCD drive geometries, ensuring compatibility and reliability in demanding applications.

Andrew McIntosh, product director of thickening services at Metso, stated: "The innovative two-piece split design allows faster installation without requiring extensive system disassembly. This not only minimizes operational disruptions but also enhances safety by eliminating the need for large cranes and suspended loads. Additionally, the SCDH4500 seamlessly integrates with existing SCD drive geometries, ensuring reliability in high-torque applications."

Metso's exceptional track record for innovation was evident in its diverse portfolio of thickening and clarifying products. The company's thickener portfolio combined advanced engineering with sustainability, catering to a wide range of applications that improved water recovery, reduced chemical consumption, and enhanced operational safety.

More information is posted at www.Metso.com.

Comments