BACKFILL: Outotec introduces modular paste backfill plant

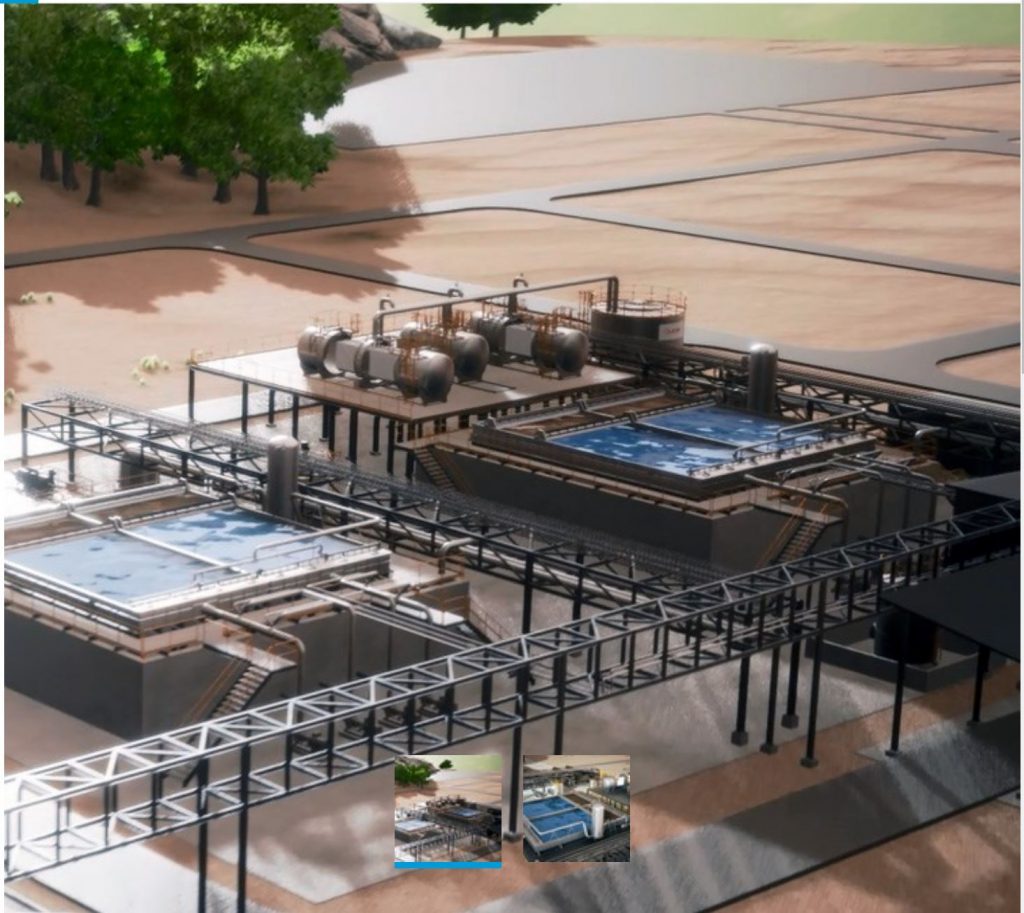

FINLAND – Outotec has introduced the Outotec modular paste backfill plant (MPB 80), designed for underground operations with low backfill throughput requirements. […]

FINLAND – Outotec has introduced the Outotec modular paste backfill plant (MPB 80), designed for underground operations with low backfill throughput requirements. […]

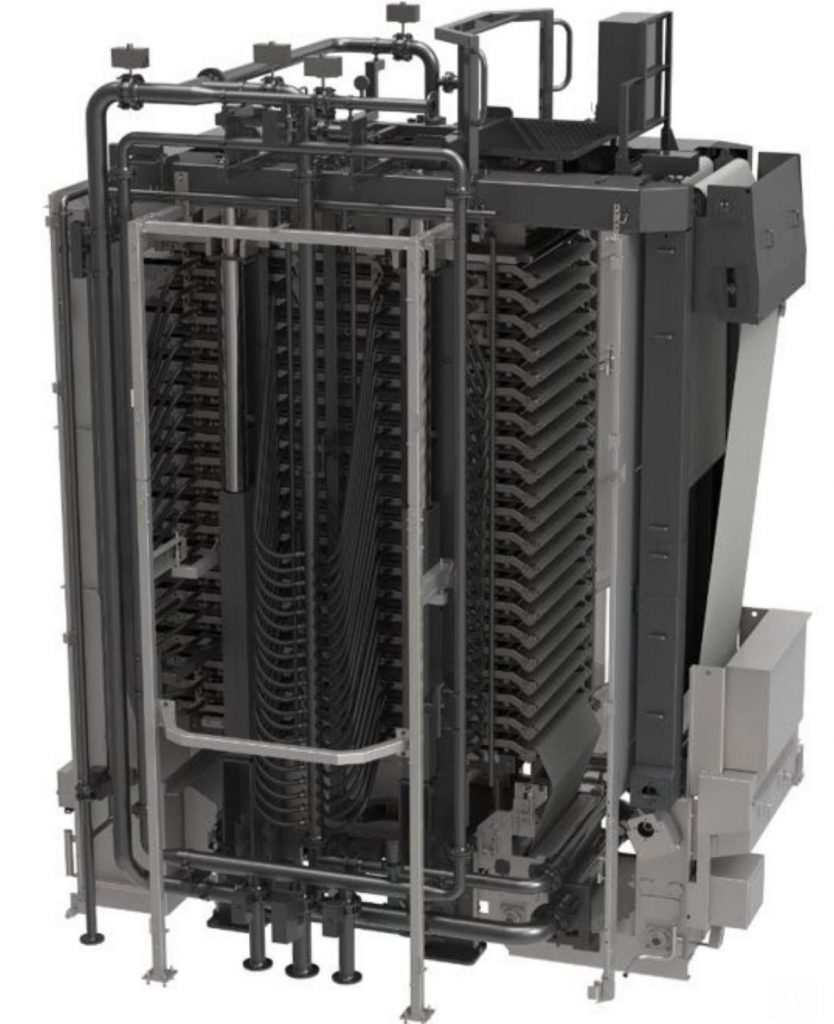

HELSINKI – Filtration applications are getting more demanding due to challenging materials, increased cake washing needs, strong acid processes, and finer particles […]