Advanced technology in belt conveyor drive pulleys: Permanent magnet direct drive pulley system

Credit: 2SP Solution Providers Inc.

This article examines the technical principles, structural features, and application effectiveness of the patented Jasung permanent magnet intelligent direct drive pulley system, designed to reduce maintenance costs and improve energy efficiency compared with traditional belt conveyor drive pulleys. The system consists of a permanent magnet direct drive pulley and an intelligent variable frequency drive (VFD), achieving deep integration of machinery, electricity, and software.

System composition and working principle

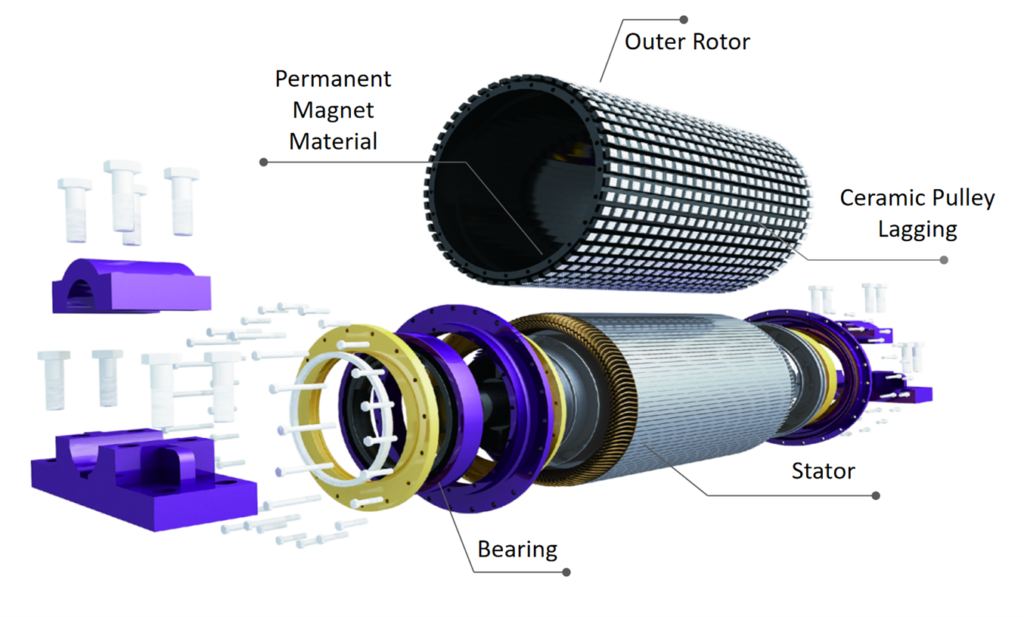

The core of the system is the permanent magnet direct drive pulley, which adopts an outer rotor permanent magnet synchronous motor structure. Its technical features are as follows:

Integrated structure: The pulley body serves as the motor rotor. Permanent magnets (UH-grade NdFeB) are embedded into the inner wall of the pulley, which is laminated from silicon steel sheets, forming the rotor magnetic field.

Fixed stator: The main shaft acts as a fixed component, fulfilling the function of the stator. The stator core (laminated silicon steel sheets) and three-phase windings are fixed to the main shaft, generating a rotating magnetic field when energized.

Drive and control: The matching intelligent VFD supplies symmetrical three-phase alternating current. Through precise field-oriented control (FOC) strategy, it drives the pulley (rotor) to rotate, thereby enabling the start-up, speed regulation, operational protection, and condition monitoring of the conveyor belt.

Specifications: 11 kW to 2000 kW drives. 0.8 to 6 metre per second belt speeds. ≤2400 mm diameters. ≤5000 t/h. X-P sealed design.

This revolutionary design fundamentally replaces the traditional multi-stage transmission chain composed of motors, reducers, couplings, fluid couplings, and mechanical pulleys.

Technical advantages and efficiency data

Energy efficiency improvement: By eliminating mechanical losses in multi-stage transmission (such as gear meshing, windage, and friction losses), the system’s transmission efficiency is significantly enhanced. Measured data show that its comprehensive efficiency can exceed 96%. Compared to traditional gear transmission systems, it achieves an energy consumption reduction of 18% to 25% under equivalent working conditions.

Maintenance cost optimization: The simplified structure directly leads to a significant reduction in maintenance requirements. The primary maintenance focus is on bearing lubrication, with a maintenance cycle extended to 20,000 operating hours. It avoids routine tasks such as reducer oil changes, gear wear replacement, fluid coupling maintenance, and alignment adjustments. Application cases in bulk material handling sectors such as ports, mining, and grain processing demonstrate that customers’ comprehensive maintenance costs can be reduced by over 35%.

Enhanced reliability: The removal of vulnerable components reduces the failure rate, significantly shortening unplanned downtime. The fully sealed (IP66) protection design ensures long-term operational reliability in harsh industrial environments such as dust and humidity.

The Jasung permanent magnet outer rotor direct drive pulley system provides an efficient and reliable power solution for belt conveyor drives through its electromechanically integrated design. Engineering application data confirms its significant advantages in improving energy utilization efficiency, reducing lifecycle maintenance costs, and enhancing system reliability. This represents a significant advancement in belt conveyor driving technology suitable for continuous conveying applications.

Bob Spicer is the managing director of 2SP Solution Providers Inc.

www.2SP.ca

Comments