Resin consolidation of large block for longhole drilling: A case study

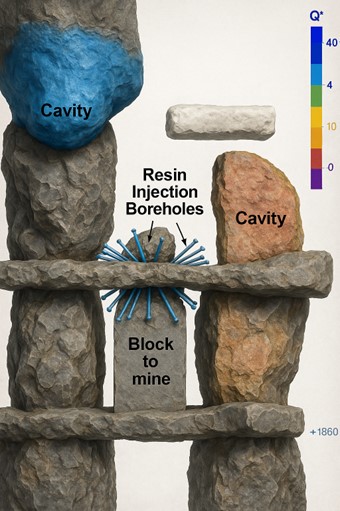

In one of Mexico’s deep hard rock mining operations, a high-value mineral block was located between unstable zones marked by fractured geology, historical collapses, and existing cavities. The block’s geometry made it difficult to split, and geotechnical conditions rendered traditional support strategies insufficient. The mine’s objective was to recover the full block in a single operation to improve productivity and avoid delays, but only if it could be done without compromising operational safety.

To achieve this, a consolidation campaign was designed and executed before initiating any longhole drilling. The goal was to reinforce not only the pillars adjacent to the block but also the overhead rock mass where cavities had formed. This case study details how a targeted resin injection solution enabled the safe extraction of a very large block under structurally complex conditions.

Engineering strategy

Weber Mining and Tunnelling proposed a pre-consolidation plan using injection of MARISIL E, a two-component organo-mineral resin. The engineering plan accounted for the unique risks posed by the block’s position and surrounding conditions — especially the presence of cavities above the block and poor-quality fractured ground along its flanks. The approach had to be both structurally robust and adaptable to varied rock mass responses during mining.

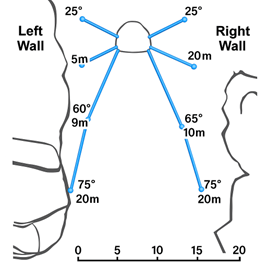

Twelve injection lines were designed, running parallel along both sides of the block. Each line consisted of four injection points per side: three angled downward to consolidate beneath the block and one angled upward to stabilize the overhead cavity zones. This configuration ensured that both the base and roof of the block were reinforced, effectively creating a shell of consolidated ground. The borehole distribution was calibrated to account for different lithologies and void spaces, ensuring no critical zones were left untreated.

Technical performance of MARISIL E

MARISIL E is designed for extreme underground environments, and its performance in this case proved essential. Once injected, the resin displayed high reactivity and consistent flow, even in variable humidity and fractured conditions.

Structural flexibility with high compressive strength

The resin forms a resilient matrix that absorbs localized deformation without delaminating. Unlike brittle grouts, MARISIL E adapts to the natural stress redistributions during drilling and caving cycles, maintaining the internal bond that holds fragmented rock masses together.

Deep and targeted penetration

Its optimized viscosity enables the resin to infiltrate tight discontinuities and microcracks. This behaviour ensures that not only large voids but also invisible internal weaknesses are structurally unified. The result is a transformation of disconnected rock into a continuous, load-bearing body.

Stable and reliable in wet conditions

Unlike systems that degrade or underperform when exposed to moisture, MARISIL E cures fully in wet or saturated rock. Its chemical bonding to damp surfaces remains unaffected, making it suitable for conditions with groundwater inflows or residual moisture.

Predictable reaction time and no expansion

The four-minute working time balances flow and cure: long enough to allow migration and short enough to minimize down time. Additionally, its non-expanding formulation ensures that injection does not trigger new fractures in the already unstable rock.

Execution

Execution began from an upper gallery with precise borehole installation using self-drilling anchors (SDAs). The injection grid followed a 12-line pattern, with injection lines spaced at fixed intervals based on the block length. Each borehole was pre-planned for a specific target zone: downward to consolidate below the block and upward where cavities had been mapped through geotechnical surveys.

The team operated using a multi-compact 1:1 pneumatic pump system, designed for accurate mixing and controlled pressure. For each borehole, resin flow was monitored in real time. Injections continued until a rise in pressure indicated full saturation of the surrounding matrix; at which point the system was purged and moved to the next point.

Crucially, injection was compartmentalized and sequenced, meaning no overlap or uncontrolled migration occurred. This allowed for the following:

- Focused reinforcement of structurally sensitive areas.

- Minimization of resin usage, avoiding unnecessary material in non-critical zones.

- Optimization of logistics: resin was supplied and applied in predictable, manageable volumes.

- Rapid progression from line to line with minimal setup time.

- This disciplined execution method enabled complete coverage while maintaining tight control over time and cost.

Outcome

The pre-consolidation allowed the mine to recover the entire block in a single extraction sequence. This brought substantial gains in operational efficiency: fewer delays, higher recovery, and no need to leave ore in place. Most importantly, the operation proceeded without structural incident: no roof collapse, no pillar failure, and no unexpected ground movement.

Post-mining inspection confirmed the integrity of both the side pillars and the previously weakened overhead section. The mine’s technical team recognized the project as a benchmark for how complex blocks can be mined safely and efficiently through intelligent use of resin consolidation.

Conclusion

This case demonstrates the value of an engineered consolidation approach tailored to geological conditions and operational needs. Careful planning, controlled injection execution, and the unique properties of MARISIL E enabled the safe extraction of a challenging block that would otherwise have required compromise or been abandoned.

By extending reinforcement not only around but also above the extraction zone, the solution addressed three-dimensional instability while delivering measurable gains in productivity, cost control, and operational safety.

Anthony Ferrenbach is general manager Americas at Weber Mining and Tunnelling, a division of Jennmar.

Comments

Doug Hambley

The system works for relatively short distances up to 20m. It did not work well for injection lengths up to 75 m at another location. The article did not discuss whether there were issues with leakage from upholes.