The mining engineer’s guide to advanced scraper strainer technology

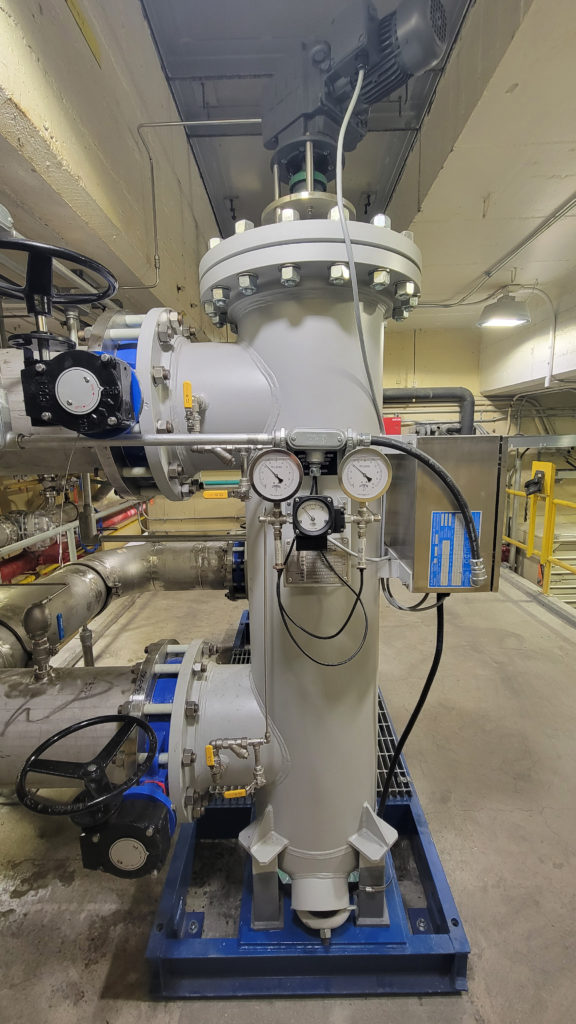

Mining engineers and plant managers oversee mineral extraction and processing while ensuring compliance with strict environmental rules. They manage slurry systems, ore processing, and vast volumes of water used in separation and dust control, maintaining reliability under abrasive conditions. With water use under scrutiny, mines seek efficient ways to strain, treat, and reuse water. Advanced water filtration — particularly automatic scraper strainers — remove debris without interrupting flow, protecting equipment and meeting discharge standards. Unlike backwash or basket strainers, they use brushes and blades for direct cleaning, requiring no auxiliary piping.

Automatic scraper strainers — cleaning the screen through direct mechanical contact using brushes and blades — are less commonly known. Many mining engineers are unaware that self-cleaning systems utilizing mechanical brushes are available. These systems offer a simpler design, eliminate the need for auxiliary piping or external water sources, and provide a more robust and adaptable operational profile. Consequently, Automatic scraper strainers are frequently overlooked because of the limited familiarity, leading to default specifications of backwash or basket strainers — even in scenarios where a scraper strainer would offer superior performance.

Strainer selection and sizing

Selecting the appropriate strainer begins with understanding the application’s process requirements, including the type and size of solids, solid loading, and what needs to be filtered.

Strainer sizing involves balancing flow rate, particle size, and solid concentration. Higher solid loading requires a larger filtration area and vessel size. As flow rate and particle concentration increase, so must the strainer’s capacity. Proper data on particle size distribution and operational conditions is critical for accurate equipment selection and sizing as well. For example, backwash strainers are sometimes specified in applications where the solids are large, sticky, or difficult to remove — conditions that backwash systems struggle to manage effectively. In these cases, scraper strainers are the better option, as their mechanical cleaning action is specifically designed to handle challenging debris. Oversizing backwash strainers can also reduce cleaning efficiency. Contrary to assumptions, bigger is not always better. Additionally, no fluid processing or filtration system remains static. Treatment conditions continually change owing to variable factors such as pressure, particle size, solids loading, and even the presence of sticky biologicals.

Flow rate and the amount of suspended solids in a fluid can vary significantly based on production demands, equipment in use, time of day, day of the week, and even seasonal conditions.

Manual basket strainers

Basket strainers are manual filters used to remove large solids or debris from a fluid stream, typically in water or process piping systems. They consist of pressure vessel housing that contains a perforated or mesh-lined basket. The basket acts as a screen to capture and retain particulates while allowing the fluid to pass through.

In water filtration applications, basket strainers are used to remove coarse materials such as leaves, sand, rust, scale, and other solids that may be present in the water. This helps protect downstream equipment such as pumps, valves, meters, and more sensitive filters from clogging or damage.

In continuous flow processes that cannot be shut down for cleaning purposes, duplex basket strainers are often installed. This type of strainer employs two distinct chambers that function independently. When one chamber needs cleaning, the flow is seamlessly diverted to the alternate chamber, enabling the removal and cleaning of the first basket.

Cleaning is a messy process that involves equalizing pressure between the baskets. If an operator fails to adequately clean the basket strainers for any reason, both strainers can become clogged at the same time. This can result in quality issues or unexpected downtime until the problem is resolved.

Backwash systems

Backwash filters are used in water filtration systems to remove suspended solids, sediment, and other particulate matter from water. They are designed to operate continuously with minimal manual intervention by automatically cleaning themselves through a backwashing process.

In normal operation, dirty fluid flows through the filtration screen, trapping suspended solids, allowing the effluent to pass through the outlet. Over time, these trapped particles accumulate and begin to restrict flow, increasing the pressure drop across the strainer.

Mining engineers are generally most familiar with backwash systems, which often leads to their default specification even in cases where scraper technology would offer a more effective solution. This tendency to standardize known designs can result in missed opportunities for performance and efficiency improvements.

Backwash filters rely on a substantial amount of flow and constant pressure, which can compromise reliability if not always available. Those units do not operate well in backwash mode below 207 kPa. To compensate, some utilize complex, pressure-inducing tactics that do not always resolve the issue. Additionally, conventional backwash units are not designed to effectively remove larger or irregularly shaped solids.

Backwash systems are also more complex and require additional control valves, instrumentation, and sometimes external water sources. Scraper strainers eliminate these needs and operate more flexibly through programmable control panels.

A key distinguishing feature of ACME’s backwash filters is that they do not require an external source of cleaning water. Instead, they utilize the system’s own process fluid for cleaning, which simplifies installation and reduces water consumption. Additionally, these filters are engineered to operate effectively at lower differential pressures, enhancing system efficiency and extending component life. Another notable advantage is the internal cleaning mechanism: the suction arm assembly rotates during backwash cycles, while the filter screen itself remains stationary. This design minimizes wear on the screen and maintains structural integrity over time.

Automatic scraper strainers

Automatic scraper strainers are a viable alternative to backwash systems in many scenarios. Unlike backwash strainers, scraper strainers do not rely on a pressurized backwash to remove solids from the screen. Instead, blades and brushes provide more reliable cleaning under varying conditions.

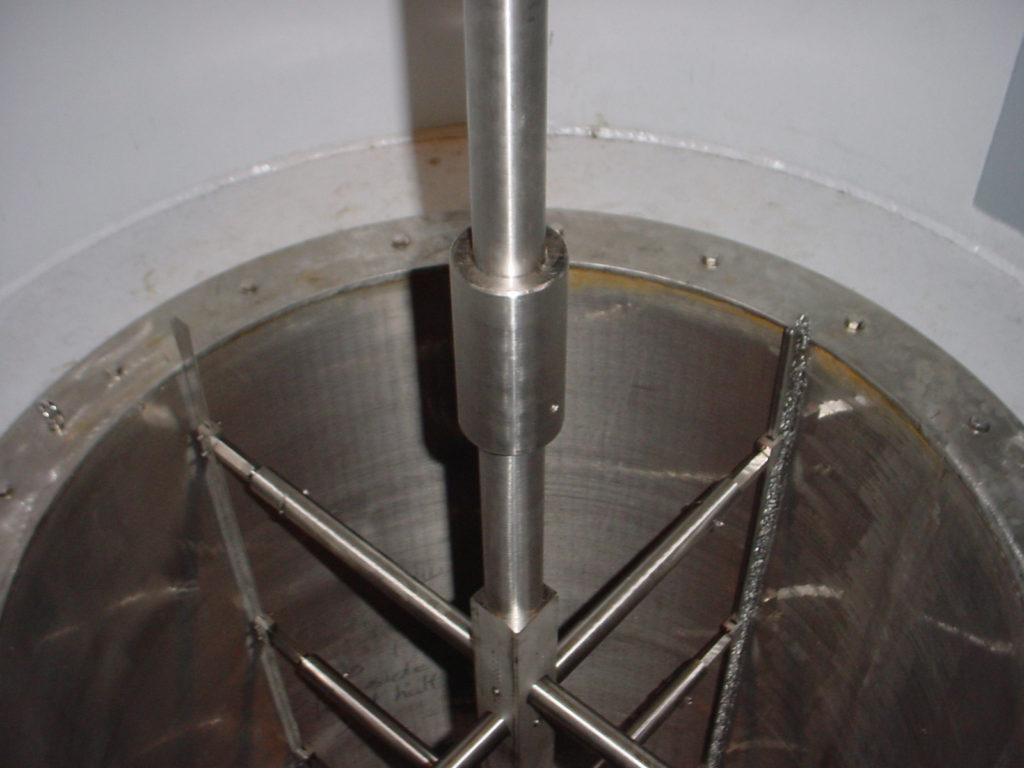

An automatic scraper strainer consists of a motorized unit designed to continuously remove both large and fine suspended solids. This process is managed by a fully automatic control system. These scraper strainers are offered with three screen types, selected based on the specific application. Reverse-formed wedge wire screens are the standard choice, valued for their durability and compatibility with brush cleaning systems. For applications requiring finer filtration, multilayer sintered metal mesh screens are recommended. In fibrous processes, perforated screens with round holes provide optimal performance.

Four blades/brushes rotate at 8 rpm, resulting in a cleaning rate of 32 strokes per minute. The scraper brushes get into wedge-wire slots and dislodge resistant particulates and solids. This approach enables the scraper strainers to resist clogging and fouling when faced with large solids and high solids concentration. It ensures a complete cleaning and is very effective against organic matter “biofouling.”

Scraper strainers allow the solids to accumulate at the bottom of the vessel, where the blowdown valve will open periodically to clear them out. Blowdown occurs only at the end of the intermittent scraping cycle when a valve is opened for a few seconds to remove solids from the collector area. Liquid loss is well below 1% of total flow.

If additional pressure is required to clean the screen, an inexpensive trash pump can be added to the blowdown line to assist in removing the solids from the strainer sump. Since the solids are small, a little trash pump can pressurize the blowdown line to evacuate solids from the strainer.

For applications with high solids loading that are prone to clogging, a macerator can be installed upstream of the automated scraper strainer to break down large solids into smaller fragments. This combination of proven technologies is already in use for some of the most demanding and debris-laden straining applications.

While standard carbon steel or stainless-steel construction is suitable for typical applications, corrosive environments such as those involving seawater, erosive slurries, or aggressive chemicals can rapidly degrade conventional equipment. This deterioration can create risks related to safety, quality, and regulatory compliance, as well as cause production downtime owing to the need for premature replacement of strainer components.

When the chemical properties and temperature of the process fluid raise concerns about material compatibility, automated scraper strainers are available in other materials such as fiber-reinforced plastic (FRP). The internal mechanism and wet components can be manufactured from super duplex or similar high-performance steels.

Cost comparison

The cost-benefit ratio of scraper strainers should factor into reduced infrastructure requirements, wear item replacement costs, and ongoing maintenance. For example, a single, automated scraper strainer can replace multiple manual basket strainers as well as the associated piping. Basket strainers require regular maintenance, with manual models requiring cleaning several times daily. The process is messy and undesirable.

While scraper strainers contain a few more wear components, such as brushes and blades, these parts are relatively inexpensive. In contrast, backwash systems can feature fewer wear parts but require more costly replacements.

As engineers become more familiar with scraper technology’s capabilities, supported by application data, installation success stories, and performance metrics, they are more likely to consider it a primary option in system design.

Jeff Elliott is a technical writer.

Comments

ANNA

WOW