Controlling carryback at conveyor transfer points

Bulk handling operations face ongoing challenges from dust and carryback at belt conveyor discharge points. Efficient discharge at transfer points demands a holistic approach, combining several components working together. This strategy aims to extend equipment life, enhance safety, and tackle the root causes of inefficiency and downtime that cut production and increase operational costs.

Primary cleaners or "scrapers" can fail for various reasons. These include increased belt speed or material volume exceeding blade specifications, changes in material properties that blades cannot handle, and inaccessibility preventing regular maintenance. Failure can also occur due to policies allowing blades to operate beyond their service life, improper installation of components, and poor design or substandard manufacturing materials.

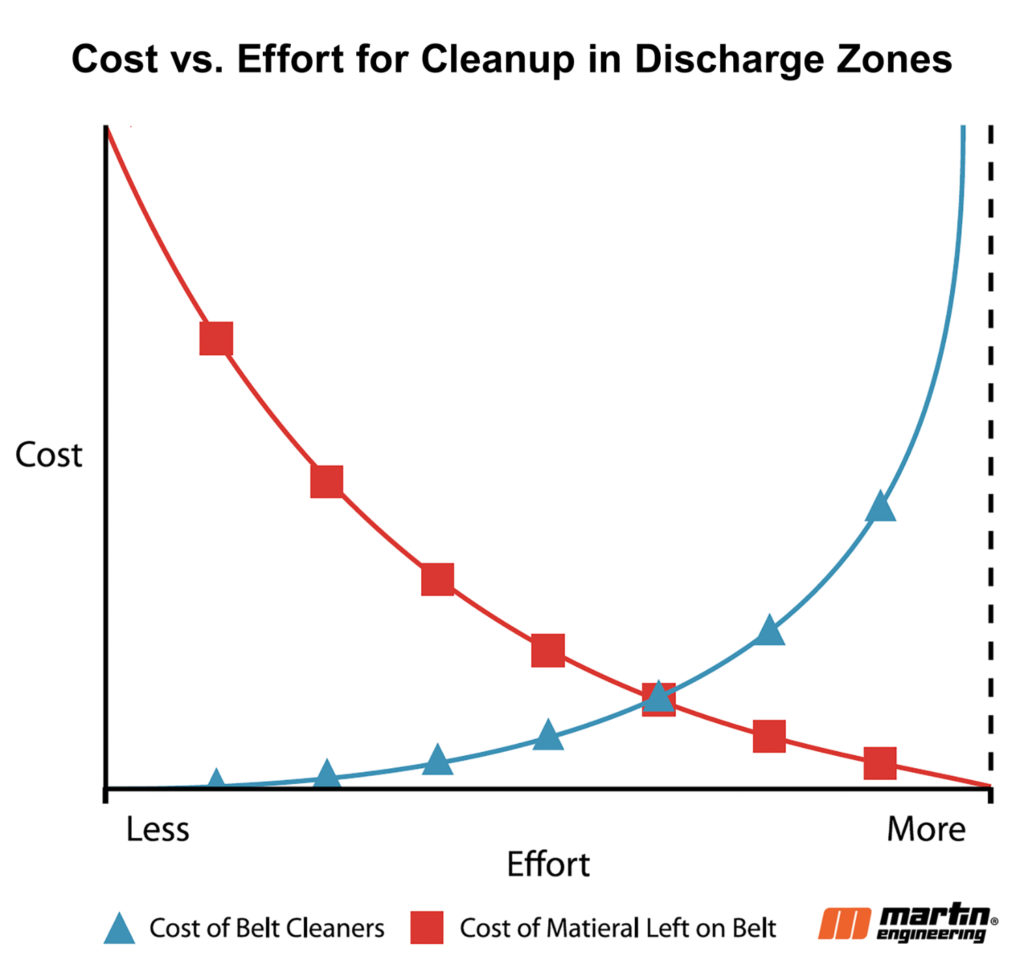

Carryback clings to the belt and spills along its return path. This spillage accumulates rapidly and can encapsulate the belt. Cleaning while the system runs poses extreme hazards. Workers who contact fast-moving belts while cleaning around running conveyors risk catastrophic injuries or death annually. Equipment like front-loaders used for cleaning can bump the mainframe, causing system misalignment and belt mistracking. Reducing cleanup needs lowers these risks and operational costs.

Various factors cause mistracking, such as crosswinds, off-center loading, or frozen idlers. A drifting belt significantly contributes to carryback when the cleaning blade misaligns with the head pulley, allowing material to bypass the cleaner.

To address these issues, operators should install a Tracker at 3 to 4 times the belt width before the discharge zone to center the belt on the head pulley. They should also consider modern cleaners like the CleanScrape Primary Belt Cleaner, which outlasts traditional blades fourfold and needs no re-tensioning or additional service after installation, reducing maintenance and improving safety.

Carryback generates significant fugitive dust as fine material in belt cracks and divots bypasses primary cleaners. Excessive dust compromises air quality, risking workplace safety violations. It obscures visibility, covers signage, and hinders access for system maintenance. Dust and fines can infiltrate return rollers and takeup pulleys, fouling bearings and causing seizures. Frozen components increase belt friction, leading to mistracking, static, and heat—major causes of belt fires. Replacing these parts requires unscheduled downtime, cutting production and raising costs.

To control dust, operators should install secondary and tertiary cleaners to thoroughly clean the belt on return. They should add a Vibrating Dribble Chute to prevent buildup on the catch slope leading to the transfer chute. Installing belt trackers or crown rollers along the lower belt path will help maintain return alignment.

Production increases can alter throughput volumes and belt speeds, exacerbating carryback, spillage, and dust issues. Retrofitting equipment to enhance safety and efficiency reduces maintenance labor costs, minimizes equipment replacements, improves compliance, and lowers overall operational expenses.

Daniel Marshall received his Bachelor of Science degree in Mechanical Engineering from Northern Arizona University. With nearly 20 years at Martin Engineering, Dan has been instrumental in the development and promotion of multiple belt conveyor products. He is widely known for his work in dust suppression and considered a leading expert in this area. A prolific writer, Dan has published over two dozen articles covering various topics for the belt conveyor industry; he has presented at more than fifteen conferences and is sought after for his expertise and advice. He was also one of the principal authors of Martin’s FOUNDATIONS The Practical Resource for Cleaner, Safer, and More Productive Dust & Material Control, Fourth Edition, widely used as one of the main learning textbooks for conveyor operation and maintenance.

Comments