Tomra tech transforms mine waste into profit

Amid mounting pressure on global supply chains, Tomra’s advanced sensor-based sorting technology is helping mining companies recover valuable resources once considered waste. This innovation extends mine life, boosts efficiency, and drives more sustainable critical mineral production.

Globally, mines possess a largely untapped aggregate opportunity. Operations generate vast volumes of waste rock, which they haul long distances, stockpile or dump, and then monitor for decades. These activities incur significant financial, environmental, and operational costs. Simultaneously, mines import aggregate for haul roads, plant foundations, tailings dams, and closure works. In remote regions, transporting suitable construction material can be prohibitively expensive, making these infrastructure projects major operational and financial challenges.

The paradox is that much of the waste rock already possesses the strength and durability required for construction use. Its limited use historically stemmed from sulphides and acid-forming material. Once operators remove these elements, the waste rock transforms into a clean, stable material that can be confidently managed, reused, or even converted into a new revenue stream. This is the opportunity that Tomra Mining’s sensor-based sorting unlocks.

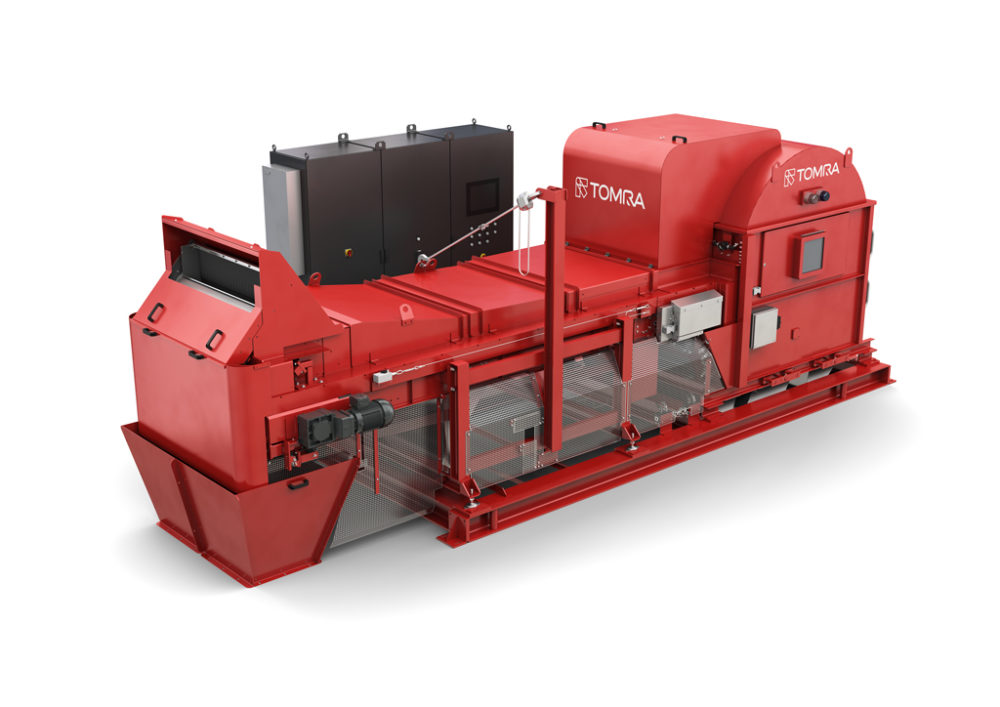

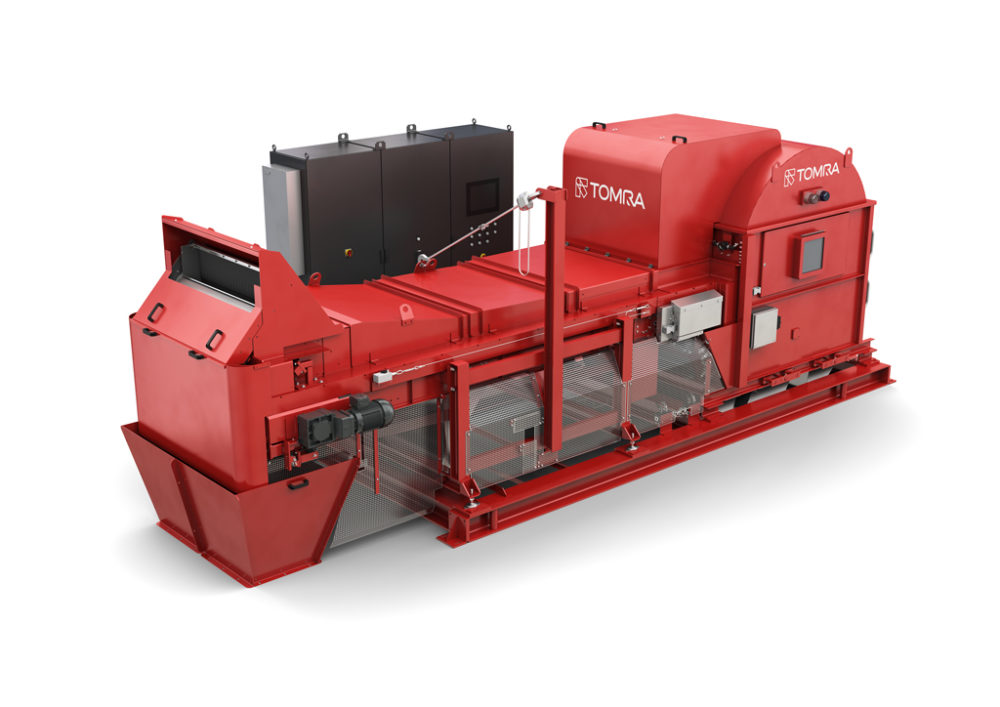

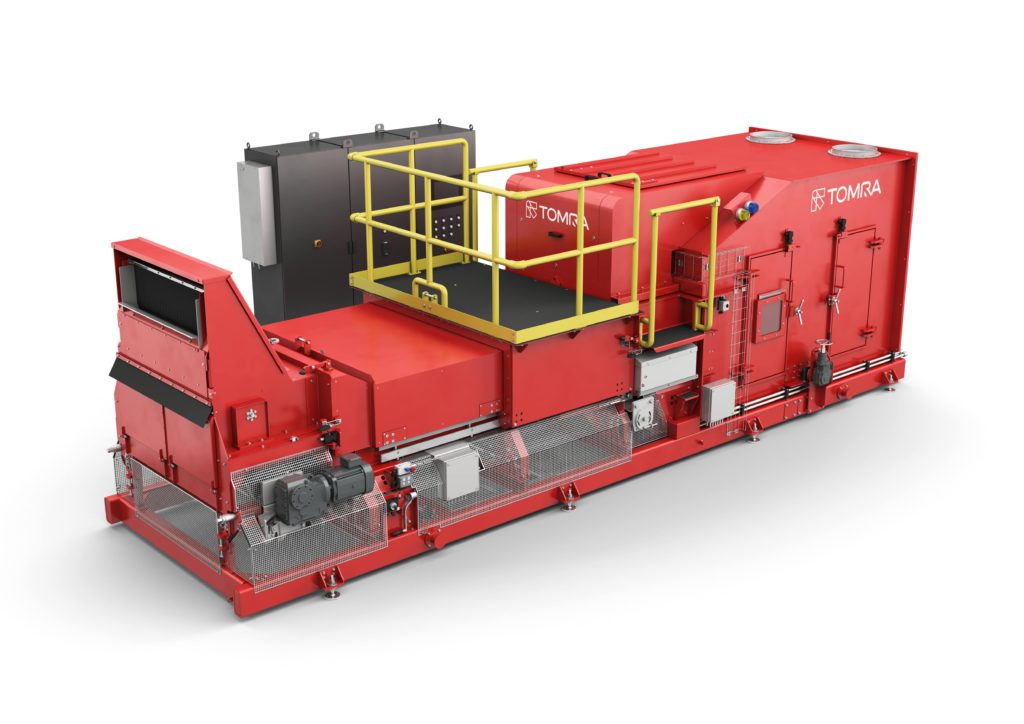

How sensor-based sorting creates value from waste rock

Tomra Mining’s sensor-based sorting allows mines to remove acid-forming material from waste rock early in the process. Using X-ray Transmission (XRT) sorting, the technology creates a detailed image of each rock, detecting fine-grained inclusions such as base metal sulphides. High-value, acid-forming particles are ejected from the feed stream, leaving barren, low-sulphide material. Operators can then manage this material with confidence, whether placing it in long-term storage, using it on-site, or selling it as aggregate. Because sorters operate on defined size fractions, mines can also retain coarse material that would otherwise be crushed away.

This allows waste to be managed in a form immediately suitable for placement, while preserving processing capacity for mineralized material. Just as importantly, sorting creates certainty. When operators certify waste rock as low in sulphides, they can simplify environmental licensing, reduce monitoring requirements, and remove that material from consideration as a future risk. This confidence underpins every commercial and operational benefit that follows.

Confidence and control: Turning waste into a manageable resource

At Bluestone’s Renison Bell operation in Tasmania, Australia, XRT sorting demonstrates its value by providing confidence and control. The technology separates non-acid-forming (NAC) from potentially-acid-forming (PAF) waste, enabling the operation to manage material according to its long-term environmental behavior.

"By separating non-acid-forming waste using Tomra XRT sorting, we are able to place a large portion of our waste rock directly in long-term storage, reducing both environmental risk and the need to place underground," The Bluestone Mining Tasmania Joint Venture stated.

This segregation simplifies waste management and closure planning by ensuring that only chemically stable material is placed in long-term storage, while PAF material is isolated and managed appropriately

At Kensington Mine in Alaska, U.S.A., XRT sorting reinforces the same principle: clean waste is usable waste. The technology recovers high-density particles containing sulphide minerals and associated gold into the concentrate stream, while rejecting low-density diorite pebbles, which are virtually devoid of sulphides, as waste. This process enhances gold recovery and produces a barren waste fraction with minimal acid-generating potential, supporting environmentally responsible tailings management.

“In the latest publicly available technical report, 4,216 ounces of gold were recovered from the pebble sorting operation in one year. At January 2026 gold prices, that represents almost US$20 million in recovered value – while still producing a clean, low-sulphide waste stream that can be safely placed or reused. That combination is what makes sorting so compelling for customers," Jordan Rutledge, area sales manager at Tomra Mining, commented.

Aggregate as a proven revenue stream

The Mt Carbine operation in far north Queensland, Australia, strongly proves waste-to-aggregate sorting. At the EQ Resources operation, ore sorting has redefined waste management. It uses Tomra XRT sorters to process tungsten-bearing ore, generating a barren waste stream that is repurposed as aggregate for sale.

“Normally you would grind the waste down to 6mm and put it through the jigs, but by putting it through the Tomra sorters, we are able to keep a whole range of aggregates on the coarser size fractions.” He continued, “The sorters remove any material containing acid-forming sulphides and the waste rock that comes out is incredibly clean. We are therefore able to use it in making all kinds of different quarry products – from road bases to concrete aggregates. It’s a perfect example of a circular economy," Kevin MacNeill, CEO of Mt Carbine mine at EQ Resources, said.

The impact on the business has been substantial, transforming the economics of the mine. MacNeill explained: “Selling these green aggregates adds a significant portion to our business – about five million Australian Dollars a year – and that’s all because of the Tomra sorters.” He concluded, “In fact, we’ve probably paid for each machine from this revenue five times over.”

Based on these results, a third sorter is now planned. Wolfram Bergbau Mittersil in Austria has also unlocked value from its waste, turning it into material for its infrastructure and for sale. Between 25 and 40 percent of run-of-mine material is removed as coarse waste through XRT sorting.

“Coarse barren material produced by XRT sorting at Wolfram Bergbau Mittersill is used for road construction at the tailings dam and in the mine, crushed as aggregate in shotcrete in the mine and local aggregate supply," Alexander Mosser, operations engineer at Wolfram Bergbau und Hütten AG, said.

Every tonne rejected before crushing and flotation is a tonne that does not enter the tailings facility, directly extending mine life where tailings capacity is the primary constraint. The ability to transport, sell, and reuse this sorted waste demonstrates it is structurally sound, logistically viable, and economically meaningful.

A second business inside the mine

These examples collectively point to a fundamental shift in how mines view waste. Traditionally, operations have functioned on a simple equation: ore generates profit, waste generates cost. Sensor-based sorting breaks that model.

By removing sulphides and producing clean, stable material, Tomra Mining enables mines to reduce liabilities, simplify compliance, extend mine life and – where market conditions allow – operate a profitable aggregate business alongside metal production. It is not just improving processing performance; it is helping mines unlock a second business inside the mine where waste is no longer defined by cost, but by value and confidence.

Comments