The right equipment investments can help mining operations lower maintenance costs

Mining operations strive to be safe, efficient, and productive, but they often allocate up to 50% of their annual budget to equipment maintenance to keep things running. How can operations run smoothly to actualize lofty production goals if you are constantly throwing money at repairs?

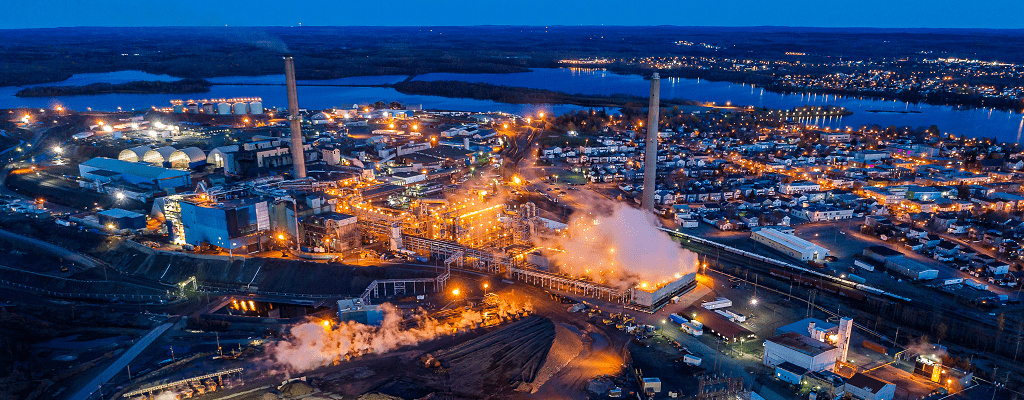

Considering the constant dust, heat, toxic substances, and crowded spaces at mining sites, operating conditions pose a significant challenge from initial mineral extraction to the byproduct handling. With all these factors during each stage of the process, unplanned downtime is costly and potentially catastrophic for an operation.

Reducing maintenance costs through equipment standardization

For mining engineers, maintenance managers, and operations managers, there is constant pressure to keep heavy material moving consistently and keep the site safe. This is an ongoing challenge given the dense composition and abrasive nature of common metals such as copper, zinc, lead, nickel, uranium, and iron ore.

Additionally, the tailings left over after the metals are separated from the rock pose another material handling challenge. These byproducts are often mixed into a slurry and pumped into storage facilities. Not only does this process demand maximum uptime from the equipment, but the material transfer of tailings is also delicate because of the presence of chemical residues, trace quantities of heavy metals, and sulfide minerals, which can threaten non-compliance with various agencies.

This means teams must strike a balance between the following:

- Equipment maintenance and performance.

- Minimizing production losses while navigating increasingly higher output goals.

- Ensuring strict compliance with OSHA, MSHA, and other regulations while answering increased demand.

With operational considerations such as these, scalable equipment that can handle large and expanding capacities of rough materials with minimal maintenance can be money-makers in a mining operation. What is a good way to achieve this? Standardize your equipment.

Cheap equipment creates more problems down the road

Sometimes maintenance managers and engineers look for cheap equipment replacements from a mishmash of manufacturers. The danger with that approach is, best-case scenario, it becomes just a replacement rather than an improvement. You can expect the same problems at some point. And the same expenses.

The harsh reality is that cheaper equipment may lead to even more maintenance issues, especially if the equipment is an off-the-shelf option, piecemealed together, or misapplied to the specific material and conditions.

Instead, a more efficient strategy for upgrades or replacements would be to standardize the equipment. Maintenance, repair, and operations (MRO) procedures become more effective when utilizing heavy-duty machines from the same manufacturer, streamlining the maintenance process and improving output. This means more revenue in your pocket because less time and resources are spent on maintenance and repairs.

Vetting manufacturers for the right material transfer equipment

The key to improving productivity and saving on potentially avoidable maintenance expenses is to invest in the right material handling equipment from the start. That means bulk material handling equipment specifically designed for the material characteristics and quantities required for your site.

Because of the critical demand for reliable capital equipment, look for the following characteristics from a manufacturer:

A proven track record: Prioritize manufacturers with a demonstrated history of supplying reliable equipment that meets the application’s requirements. References from other operations are invaluable.

Durable components: The durability of every component is important — motors, gearboxes, bearings, troughs, and much more — in extending the equipment’s lifespan and minimizing its maintenance.

Expert consultation and engineering: Although it may cost more upfront, custom-made equipment for your site offers better lifetime value. Find a manufacturer that helps you through the spec process and does not tighten a single bolt until they know precisely what you need the machine to do.

Designed for maintainability (DFM): The equipment should be designed with scalability and ease of maintenance in mind. This means easy access to lubrication points, replaceable wear parts that can be quickly swapped out, and standardized components.

To summarize, mining companies often spend 30% to 50% of their annual budgets on equipment maintenance, underscoring the need for reliable, durable material handling equipment to minimize downtime and expensive repairs. Operations can mitigate high maintenance costs by standardizing their heavy-duty equipment, such as conveyors, bucket elevators, stacker-reclaimers, and apron feeders. These pieces of capital equipment are the primary drivers of productivity in mining operations and are costly when they are forced to shut down. Finally, working with a reputable manufacturer to design and build bulk material handling equipment tailored to your specific material and jobsite conditions can go a long way in helping to reduce maintenance costs and improve production in the long run.

Andrew Parker is president of CDM Systems, Inc. He has more than 20 years of experience in the bulk material handling industry. He oversees operations, including conveyor design and development. To learn more, visit cdmsys.com/consulting.

Comments