Gekko ILR and Carbon Scout boost gold recovery at Stawell mine

A recently released case study explains how the Gekko InLine Leach Reactor and the Carbon Scout helped reduce soluble gold losses at Stawell gold mine 240 km northwest of Melbourne, Australia.

Production began in 1981, but the mine was put on care and maintenance in 2016 for two years. With the decision to restart production came the need to upgrade and automate the mill. Gold is recovered in a 2,400-t/d plant that includes milling, gravity recovery, flotation and carbon-in-leach (CIL).

The ILR 1000BA was installed at the Stawell mine in 2018 as part of the upgrade project and has been running ever since. The unit treats up to 3 tonnes of high-grade gravity concentrate per batch within 24-hour cycles. The ILR unit achieves over 98% recovery and is currently contributing 40% of total gold production.

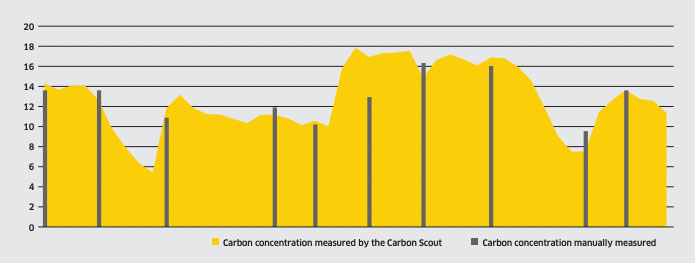

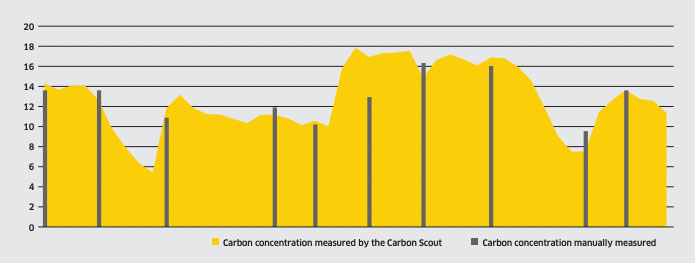

The Gekko Carbon Scout was installed at Stawell in 2019. The aim of the project was to provide a fully automated carbon movement system that can be operated from the control room and automatically transfer the carbon from each tank as it loads the gold from solution. The X-ray fluorescent (XRF) functionality was later installed in 2021, allowing the operation to calculate real time gold in circuit (GIC) inventory (which is currently being tested and optimized).

Since installation, the Carbon Scout has undergone further development based on the feedback from Stawell personnel. Challenges such as piping positions, valve specifications, and laser level positioning have been overcome. Gekko is updating Carbon Scout units at other installations.

Contact the manufacturer at www.Gekkos.com for technical information.

Comments