Hexagon introduces 3D camera for production material monitoring

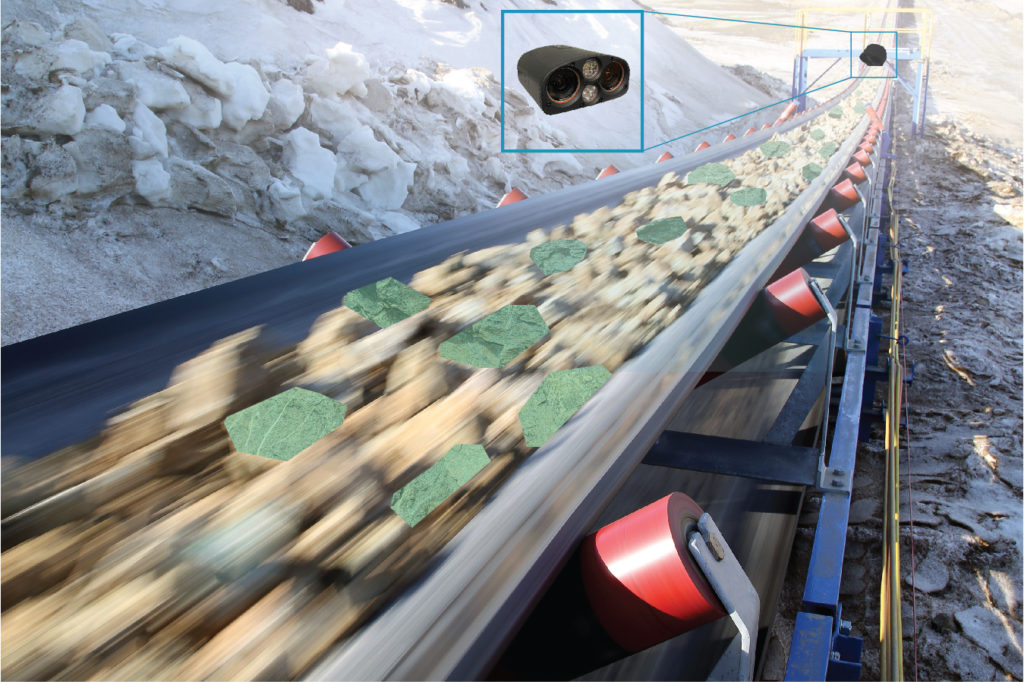

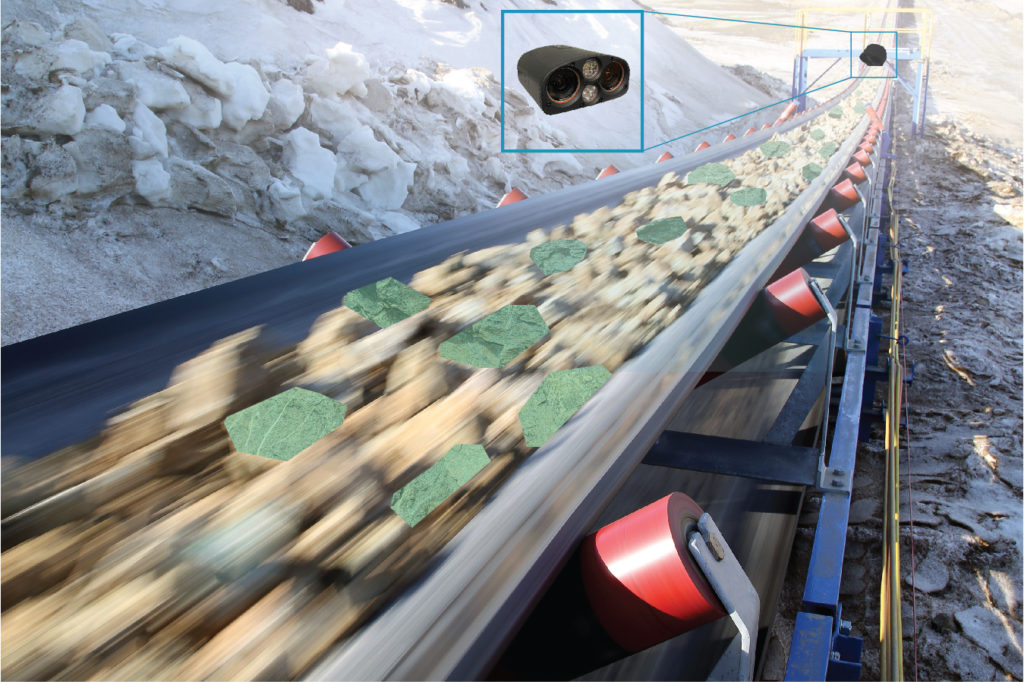

Hexagon’s mining division has strengthened its leadership in production material monitoring and measurement by introducing HxGN MineMeasure Detect, a 3D camera hardware, software and data solution. MineMeasure Detect enables real-time optimization for plant production with automated digital image analysis offering continuous, accurate and rapid measurement of oversize, volume, rock fragmentation and color analysis.

Mines demand consistent, predictable, high-volume production with plants intended to operate 24/7. Changing geologic mineral and structural conditions within the ore can sometimes mean oversize particles block crushers, chutes and conveyors. Blockages can halt operations, in severe cases resulting in lost operational revenues worth millions of dollars.

MineMeasure Detect minimizes production interruptions and costly downtime with oversize detection of large particles. It enhances production efficiencies and reconciliation by calculating volume, density and tonnage. Advanced detection reveals an aggregate of previously unmeasured ancillary variables, such as material density and hardness, which is essential to throughput maximization and ore liberation.

The solution’s fragmentation analysis capabilities enable continuous monitoring and improvement of production throughput while managing costs. Industry-leading research and proven algorithms for direct measurements of particle identification and fines identification set MineMeasure Detect apart for its measurement accuracy in mineral processing. It includes the largest set of data availability applied across the international mining industry. Colour-analysis data for ore detection give operators additional opportunities to adjust material handling, material blending, clay detection and ore treatment recipes.

“MineMeasure Detect is built on more than 25 years’ experience partnering with international mining operations, allowing systems to be fully integrated with customer technologies,” said James Dampney, VP, MineMeasure, Hexagon’s mining division. “Combined with our fragmentation tools, the solution’s immediate detection capabilities offer a critical early warning for operators to avoid catastrophic production stoppages.

“With its image-analysis techniques ensuring that fragmentation is managed and optimized, MineMeasure Detect fits seamlessly in the MineMeasure portfolio, which delivers scrutiny and transparency in every step of the ore extraction journey.”

Learn more at hexagon.com.

Comments