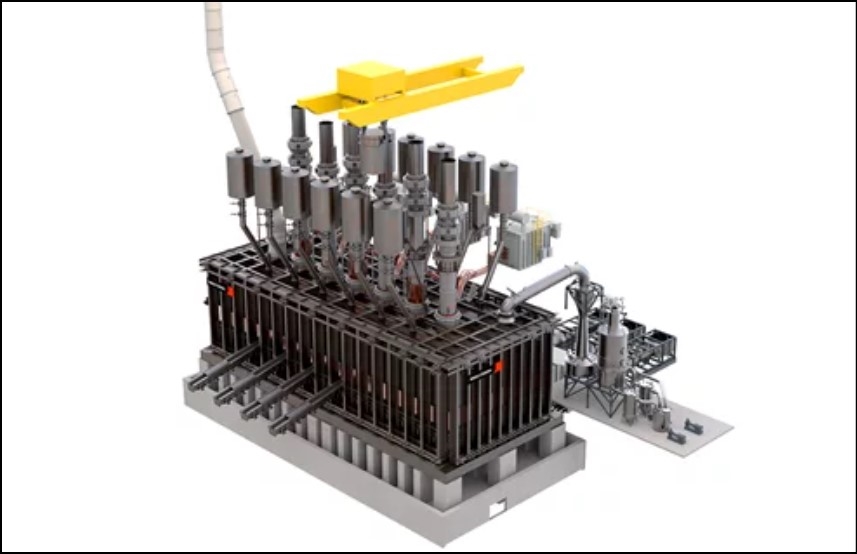

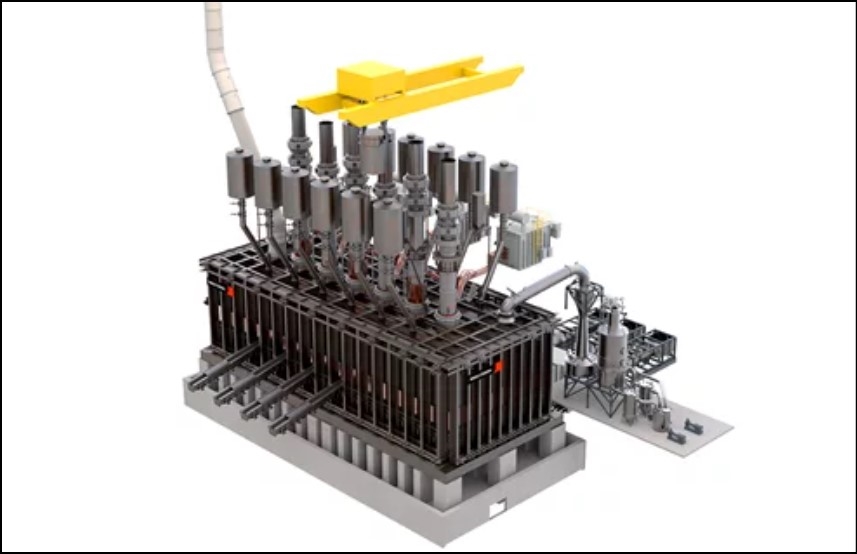

Metso Outotec launches DRI smelting furnace to decarbonize iron and steel industry

Metso Outotec is launching the innovative DRI (direct reduced iron) smelting furnace to substitute blast furnaces for iron and steel making. The DRI furnace is one of Metso Outotec’s key solutions for decarbonization of the iron and steel industry, which currently produces about 8% of the global carbon dioxide emissions.

“The DRI smelting furnace is a true breakthrough technology. It will help the iron and steel industry to reach their CO2 emission reduction targets and limit global warming. The new high-capacity six-in-line DRI smelting furnace is part of Metso Outotec’s Planet Positive offering, which is focused on environmentally efficient technologies,” says Jyrki Makkonen, VP smelting at Metso Outotec.

DRI smelting furnace technology is based on proven Metso Outotec equipment. The furnace and related products are complete and ready for implementation. Customer-specific pilot-scale testing will be conducted in the Metso Outotec research facilities to demonstrate large-scale DRI smelting.

The DRI furnace uses easily available furnace-grade iron ore instead of DRI-grade iron ore by managing larger volumes of slag than can be handled by electric arc furnaces. It can be integrated with Metso Outotec’s hydrogen-based Cicored process or other direct reduction processes.

DRI smelting technology development continues to further optimize the process for customer-specific feed materials and to complement Metso Outotec’s Planet Positive offering for decarbonization of iron and steel industry.

Metso Outotec’s DRI Smelting Furnace provides the following benefits:

More information about the Metso Outotec DRI Smelting Furnace is available on the website.

Metso Outotec will host two free webinars where the DRI smelting solution will be discussed in more detail. The events will take place on Nov. 8 at 10:00 a.m. and Nov. 15 at 10:00 a.m. EET. More information on the webinar, including registration details, can be found here.

Comments