February: The role of biotechnology in mining and minerals

As the global demand for metals continues to grow year over year, the need for intensive mining is showing no signs of slowing down. In fact, some reports project that production of battery metals is expected to increase by 500% by 2050. This unprecedented demand is also being met by a two-fold supply problem; the slow speed of new mining operations coming on-line and the general problem of world-wide low ore grades that has surfaced over the last few decades.

The global market needs to grapple with these problems and producers need to find ways to extract metals quickly and cheaply while still adhering to environmental, social, and governance (ESG) responsibilities which have become critical guiding principles of late. One burgeoning area of technology that is potentially valuable in solving some of these issues is biotechnology.

Generally speaking, biotechnology involves the use of processes that are facilitated by cells or their components to achieve a specific end-goal. For the mining sector, biotechnologies have been proposed or established for a range of applications, but most notably the pre-treatment (bio-oxidation) with microbes of refractory gold- or copper-bearing materials prior to cyanidation, and the use of microbial surfactants to extract high mineral yields from low-quality ores.

In fact, variations of the former bioprocess have enjoyed commercial success since the 1960s. In situ bioleaching, for example, was used in Canada in the 1970s to recover uranium from deep mines, and at the Denison mine alone, an estimated 300 tonnes of additional uranium were extracted after the main phase of mining using bioleaching. Similarly, when used in stirred tank bioreactors that are set up as continuous feed systems, bio-oxidation can help process 40 to >8,000 tonnes of concentrate per day, as was first shown in Fairview mine of Barberton, South Africa, in 1986. Metso Outotec’s in-line BIOX bacterial oxidization process is perhaps the most widely deployed biotech solution over the long-term with a presence in over 13 plants, and Toronto-based, BacTech Environmental’s BACOX analogue has also seen significant success in South American gold operations.

In all these cases, the use of microorganisms in mining initiatives is described as highly advantageous: they are considered cost-effective and environmentally benign, with lower carbon footprints and abilities to liberate (in some cases, selectively) valuable metals from complex materials that are otherwise recalcitrant to standard pyrolytic and hydrometallurgical techniques.

Accordingly, recent biotech developments seek to use micro-organisms to process solid wastes, extract metals from oxidized ores, and to selectively recover metals from process waters and waste streams. The recycling of electronic, urban waste respectively is of particular interest given its high metal content and accessibility. In one laboratory study out of Switzerland, the leaching of fine-grained electronic scrap at concentrations of 5 and 10 g/L, respectively, with Thiobacilli (bacteria) allowed for recovery of 90% of the available aluminum, copper, nickel, and zinc at 30°C. While these results are undeniably micro-organism and condition-dependent, they do show comparable recoveries to certain hydrometallurgical techniques in the patent literature (up to 92%) without the need for the strong acids and energy-intensive temperatures (>60°C) of the latter. Given that Canadians are generating around 725,000 tonnes of e-waste annually, in one of the fastest growing waste streams in the world, with roughly $10 billion worth of gold, platinum, and other precious as well as battery metals dumped globally as per a new UN report, the development of biorecycling techniques is required.

Despite the promise and success of biotechnologies, however, there has been relatively little adoption of said technologies into industrial flowsheets. Various studies suggest that the issue is multifactorial, but is broadly linked to the sector’s problem-solving approach to innovation, since there is little room to enhance profitability via product differentiation. In other words, predominant innovation drivers include the push for improved processes that can reduce risk and costs (of current operations or developing new mines) and increasing asset productivity.

Consequently, biotechnological innovations must be more than simply eco-friendly alternatives to conventional processes; they must outperform or match the efficacy of their chemical analogues, allow for incremental adoption to reduce risk of failure, and be highly cost-effective to scale and implement (with preference for “bolt-on” or “in-line” solutions). This requires spaces to prototype and evidence their efficacy through the capture of irrefutable data, but also requires knowledge brokers to champion and socialize candidate solutions that are viable across the sector.

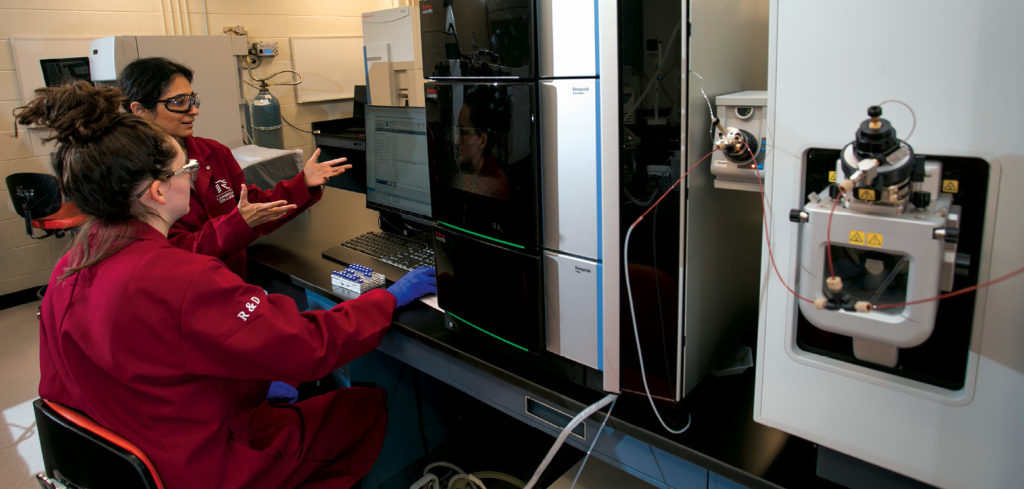

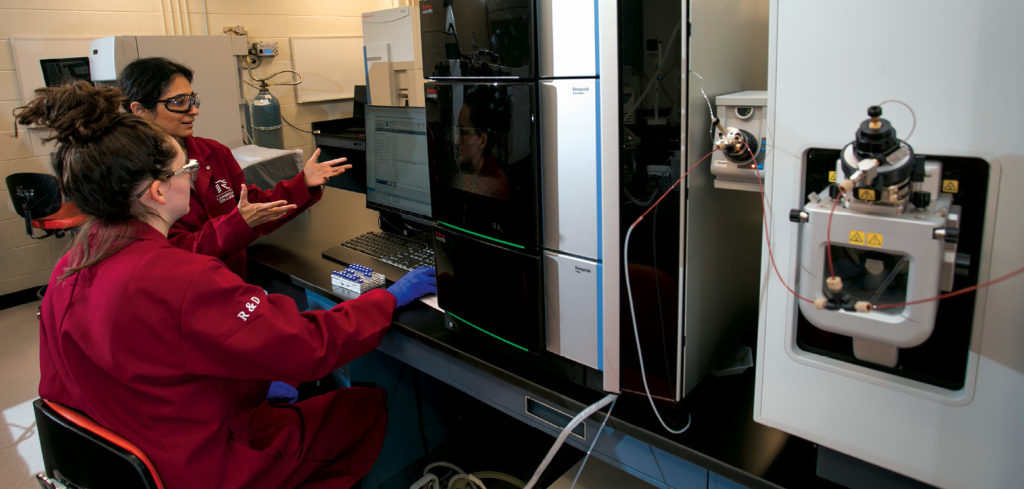

These, incidentally, are key characteristics of applied research centers like Cambrian R&D and the Centre for Smart Mining at Cambrian College, which are poised to become vital pieces in the mining ecosystem for biotechnology adoption. As an example, in partnering with Dr. Nadia Mykytczuk, a world-leading researcher in biotech, at Laurentian University, Cambrian was able to facilitate the design and build of bench-scale bioreactors that removed 78-90% of problematic arsenic from tailings over the span of six months. This successful collaboration partly forms the basis of Mykytczuk’s ongoing work with BacTech, which recently filed a provisional patent on processes that can be used to extract critical battery metals from mine tailings in Sudbury.

Finally, what stands in the way of mass-adoption of promising biotechnological solutions in mining and mineral processing are barriers not unfamiliar to those in the sector. Solutions that have easily quantifiable returns on investment, manageable disruption to existing processes, and minimal investment in human capital and skills upgrading will tend to win out. Systems that are turn-key or that are provided “as a service” that show value early on may indeed pave the way for an influx of biology-based techniques that can unlock great benefit to the sector.

Dr. Madiha Kahn is an analytical research lead at Cambrian R&D.

Steve Gravel is the manager of the Centre for Smart Mining at Cambrian College.

Comments