[caption id="attachment_1003724200" align="aligncenter" width="532"]

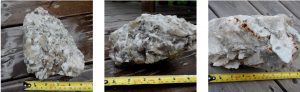

Samples collected from the Main dyke at the Case Lake lithium property. (Image: Power Metals Corp.)

Samples collected from the Main dyke at the Case Lake lithium property. (Image: Power Metals Corp.)[/caption]

ONTARIO – Vancouver-based

Power Metals and its 20% partner

MGX Minerals have sent a 10-km sample of core for testing from the Case Lake lithium project 130 km northeast of Timmins. Bench-scale metallurgical tests of the spodumene rich material are being done by Orion Labs and Light Metals International (LMI).

The core samples are undergoing chemical and mineralogical homogeneity tests with the goal of producing a 95% spodumene concentrate. Once that level of purity is achieved, work will begin to develop a hydrothermal leaching process to make an even higher grade concentrate.

MGX, Orion and LMI are developing a thermochemical technology to extract lithium carbonate and/or lithium hydroxide from a variety of spodumene concentrates. According to Power Metals the method is modular and highly scalable and has the potential to substantially cut production costs. Much of the savings will be achieved by the elimination of sulphuric acid leaching.

The Case Lake property has at least five dykes that are exposed at surface and are open along strike. The dykes exhibit various minerals – the North and Main dykes have spodumene rich zones, the Northeast dyke has very course grained spodumene, the South dyke has no spodumene, and the East dyke has course grained feldspar, quartz and minor other minerals.

Find more information at

www.PowerMetalsCorp.com.

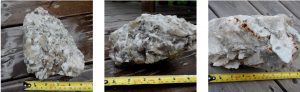

Samples collected from the Main dyke at the Case Lake lithium property. (Image: Power Metals Corp.)[/caption]

ONTARIO – Vancouver-based Power Metals and its 20% partner MGX Minerals have sent a 10-km sample of core for testing from the Case Lake lithium project 130 km northeast of Timmins. Bench-scale metallurgical tests of the spodumene rich material are being done by Orion Labs and Light Metals International (LMI).

The core samples are undergoing chemical and mineralogical homogeneity tests with the goal of producing a 95% spodumene concentrate. Once that level of purity is achieved, work will begin to develop a hydrothermal leaching process to make an even higher grade concentrate.

MGX, Orion and LMI are developing a thermochemical technology to extract lithium carbonate and/or lithium hydroxide from a variety of spodumene concentrates. According to Power Metals the method is modular and highly scalable and has the potential to substantially cut production costs. Much of the savings will be achieved by the elimination of sulphuric acid leaching.

The Case Lake property has at least five dykes that are exposed at surface and are open along strike. The dykes exhibit various minerals – the North and Main dykes have spodumene rich zones, the Northeast dyke has very course grained spodumene, the South dyke has no spodumene, and the East dyke has course grained feldspar, quartz and minor other minerals.

Find more information at

Samples collected from the Main dyke at the Case Lake lithium property. (Image: Power Metals Corp.)[/caption]

ONTARIO – Vancouver-based Power Metals and its 20% partner MGX Minerals have sent a 10-km sample of core for testing from the Case Lake lithium project 130 km northeast of Timmins. Bench-scale metallurgical tests of the spodumene rich material are being done by Orion Labs and Light Metals International (LMI).

The core samples are undergoing chemical and mineralogical homogeneity tests with the goal of producing a 95% spodumene concentrate. Once that level of purity is achieved, work will begin to develop a hydrothermal leaching process to make an even higher grade concentrate.

MGX, Orion and LMI are developing a thermochemical technology to extract lithium carbonate and/or lithium hydroxide from a variety of spodumene concentrates. According to Power Metals the method is modular and highly scalable and has the potential to substantially cut production costs. Much of the savings will be achieved by the elimination of sulphuric acid leaching.

The Case Lake property has at least five dykes that are exposed at surface and are open along strike. The dykes exhibit various minerals – the North and Main dykes have spodumene rich zones, the Northeast dyke has very course grained spodumene, the South dyke has no spodumene, and the East dyke has course grained feldspar, quartz and minor other minerals.

Find more information at

Comments