September: Four new gold pits underway

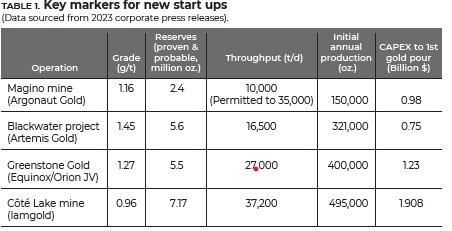

It has been decades since the Canadian mining sector has seen multiple open pits under construction. Four new gold open pits are coming onstream in the next six months, setting the stage for heightened commissioning activity. The new operations will contribute over 1.3 million oz. of annualized gold production when fully commissioned. If all goes as planned, in 2024, Canadian gold production should exceed 8 million oz. of gold and set the stage to surpass the national gold production record set in 2021.

All these projects are far from “cookie cutter” and are adapting to the jurisdictions they are operating in. Both Magino and Greenstone will have on-site natural gas generated power due to the lack of available capacity from the grid, while Côté Gold made significant design changes through the incorporation of a high-pressure grinding roll (HPGR) and vertical grinding technology to maximize the utilization of available grid power. The Blackwater project is constructing a 135 km 230 kV transmission line to provide power to the site and utilize three-stage crushing to initially keep power consumption low.

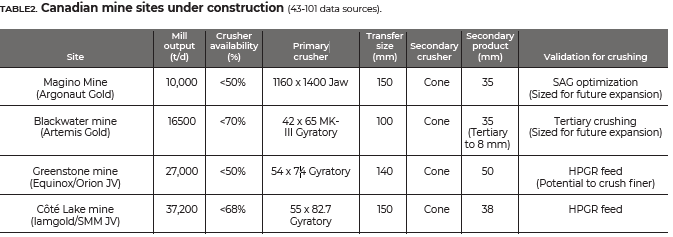

All the sites have sized the material handling equipment for later expansion opportunities. Utilizing 140- to 231-tonne haul trucks delivers lower operating costs, without the need for elaborate maintenance equipment. Three sites have incorporated gyratory crusher for primary crushing stages – to enable later expansion phases. The Magino site will utilize a jaw crusher, with the provision of a secondary cone crusher stage to provide optimal feed to the SAG mill. It is more common practice to utilize two stages of crushing ahead of any downstream option – SAG or HPGR, since the operational characteristics improve dramatically when controlling the top size to any mill circuit.

The Magino mine start up has been event free, with 3,295 oz. produced as of June 30, 2023. The company has incurred $730 million of the $755 million budgeted to complete the project. Commercial production is on track for Q3 2023. The team will be quite active converting in-pit resources into reserves, along with testing structures to the west and high-grade targets below the pit shell. An optimization and expansion review of the mill will also take place in Q3 – with the goal of increasing production beyond current levels. With the high-grade Alamos Gold Island gold mine immediately adjacent to Magino, it will be exciting to see the exploration results from the next phase of exploration.

Artemis is seeing considerable progress at the Blackwater site – with an estimated 27% of the project completed. The mill building is set to be erected and enclosed by the end of 2023, which is an important step forward and reflects the hard work and expertise of the entire team. Another exciting development is the upcoming delivery of the first 240-tonne Cat 793 haul truck by the third quarter of 2023. The haulage fleet will be a combination of Cat 785 and Cat 795NG haul trucks and complemented with 22 to 34 m3 hydraulic excavators. The truck delivery marks a crucial moment and will pave the way for increased pit development.

Despite forest fire restrictions, construction progress remains on schedule for the second half of 2024. All construction activities were suspended due to the extensive wildfire activity in central B.C. during July 2023. The team’s careful planning and ability to secure staffing from recently completed construction projects have ensured timelines are met despite unforeseen events. An important milestone has been achieved with 160,000 hours of operations without a lost time injury frequency rate (LTIFR), highlighting the project’s commitment adherence to protocols and employee well-being.

Artemis is actively planning to achieve carbon neutrality at the Blackwater site by 2029. An option agreement with Caterpillar to supply zero-emission vehicles with a targeted order date of 2025 is in place. All electrified equipment should be on-site for 2029. The site will benefit from receiving B.C. Hydro’s low cost and reliable grid power to meet this goal.

The Greenstone Gold project is rapidly advancing towards construction completion with crews shifting focus to operational readiness and commissioning. The project had the unusual complexity of rerouting a major highway and building a 65 MW natural gas-powered generating plant – both of which are substantially completed, with the power plant being commissioned soon.

The equipment requirements of this site are unique owing to the strip ratio and layout of the deposit. Two of the six Epiroc Pit Viper 235s are operational for 10 metre bench drilling. One of the 29 m3 Komatsu PC5500 shovels is operational with the remaining units operational in the coming months. Eight of the Cat 793s out of the fleet are running and preparing for the startup.

The final dimensions of the open pit will be 1.8 km long, 1.0 km wide, and 600 metres deep. The mine design is unique in that the open pit will be dealing with intersecting historic underground workings as mining advances. Underground voids will be filled with sand or rock fill as needed.

Mining of the Greenstone open pit will occur in five main phases preceded by a starter pit. Waste rock will be placed in five distinct waste dumps with four located around the pit and one further to the south. The open pit will generate 690 million tonnes of overburden and waste rock over the life of mine (LOM) for an average LOM strip ratio of 5.1:1. Reserves equal 135 million tonnes of ore at 1.27 g/t Au.

Finally, the Côté Gold mine will start commissioning in Q4 of 2023. Operating at a planned throughput of 37,200 t/d – this site will churn out close to 500,000 oz. of gold yearly – with significant resource potential to grow further.

A conscious effort to maintain a safe work environment is front and centre at this mine. In early 2023, the mine surpassed 10 million project hours with a lost time injury frequency rate (LTIFR) at 0.02, which is clear evidence of a workforce that embraces a Zero Harm attitude. The construction team recently added an additional 264 beds to the camp to ensure sufficient accommodation for up to 1,900 workers on-site in June.

The site completed the extensive tailings management facility raise just before the spring freshet and created sufficient water storage capacity for commissioning activities. All civil works and structural steel are in place, with the high-pressure grinding roll positioned in place and quickly advancing to commissioning in Q4 of 2023. The installation of crucial components like CIP tanks, Vertimill mechanical works, and associated structural steel, as well as cyclone installations, has reached an advanced stage.

A unique feature of this site is the implementation of an autonomous mining fleet. Ten autonomous vehicles have been commissioned thus far, including Atlas Copco Pit Viper 231s (to drill 12 m benches) and a combination of Cat 6060 electric shovels and Cat 793F haul trucks. Three Cat 994s will also be on-site for loading and stockpiling. Remarkable accomplishments in training are evidenced by owner mining teams managing over one million tonnes in Q1 of 2023.

The installation of a Weir Minerals 2.4 by 2.4 metre HPGR will mark the largest scale installation of an HPGR in Canada. This single HPGR will utilize 7,800 kW of power to crush up to 1,596 t/h into an 80% passing 2.4 mm product for the ball and Vertimill circuits. Pilot stage grindability test work indicated the Côté Lake deposit material is very competent and resistant to SAG milling. A typical SAG mill configuration, even with high ball loads, would not be energy efficient. Test work conducted at COREM using HPGR technology confirmed metallurgical and economic advantages over SAG milling in a more traditional flowsheet. The HPGR provides metallurgical benefits by inducing micro cracking in the ore which improves the cyanide leach kinetics that would not be possible if a conventional flow sheet were utilized.

Grid connection to the provincial hydro grid will be completed soon and will provide 56 MW of power required for this plant. By incorporating an efficient crushing design, HPGR, and Vertimills, the project team mitigated risk by designing a plant with available grid power.

The most interesting facet about the Côté Gold project is the potential upscale of the reserve base. With the recent inclusion of the Gosselin zone into the resource category, measured and indicated resources now exceed 490.4 million tonnes at 0.9 g/t equating to 13.56 million oz. of gold. A 15,500 metre drill program slated for this year is positioned to expand the Gosselin zone, as it is still open at depth and on strike to the west.

To observe four open pit projects come online with unique solutions for their operating challenges is quite interesting to anyone in the business. The ramp up of these mines will undoubtedly improve how we build and operate other mines that are in the later stages of development.

Steve Skjonsby is a freelance writer.

Comments