Martin Engineering celebrates 50 years of air cannon technology

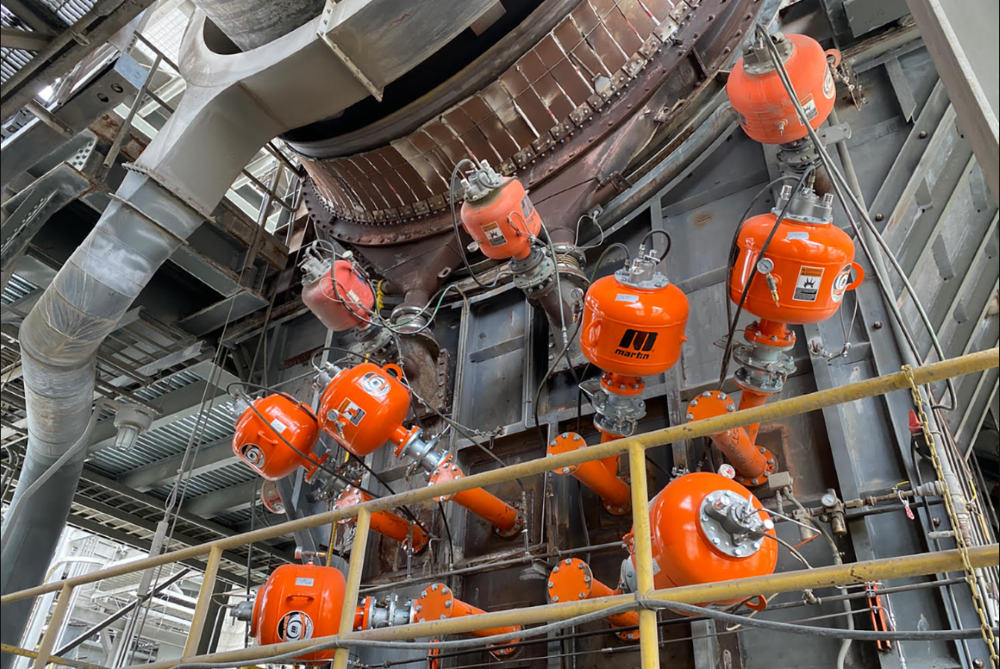

The world leader in bulk handling solutions Martin Engineering is marking the 50th anniversary of its invention of the world’s first low-pressure air cannon.

Air cannons have transformed material flows in bulk processing systems, eliminating problematic internal buildups and blockages. After five decades of continuous innovation, Martin Engineering remains at the forefront of air cannon advancements, enabling industrial plants to run more profitably, efficiently, and safely than ever.

“We’re especially proud that Martin air cannons have become so important in reducing the health and safety risks associated with clearing blockages manually – such as working in confined spaces, working at height, falling materials, and working in hot and dusty environments,” said Brad Pronschinske, Martin Engineering’s global air cannon product manager. “Our team is always working on new developments and we’re looking forward to bringing the next generation of air cannon technologies to our customers all over the world.”

The company launched the world’s first low-pressure pneumatic air cannon – its legendary Big Blaster – in 1974. It was devised and developed by Carl Matson, a member of Martin’s senior team and cousin of the firm’s founder Edwin F. Peterson. Martin air cannons soon proved to be a game-changer for sectors such as cement, for the first time signalling an end to workers having to access the interior of preheater vessels to manually break off hefty material build-ups using a high-pressure water jet – one of the most unpleasant and hazardous jobs on a cement plant.

By the 1990s Martin Engineering had developed an extreme heat and velocity version of the Big Blaster, the XHV. In the 2000s Martin became the first to introduce safer positive pressure firing valve with its Tornado air cannon. Designed with safety in mind, the positive firing valve also delivers a more powerful blast. Soon after that came the introduction of the Hurricane valve, located in the rear of the air cannon tank at the tank and nozzle junction, greatly improving safety and ease of maintenance.

Then came SMART Series nozzles with multiple nozzle tips, one of which features a retractable design that extends the 360° nozzle head into the material stream only when firing and the Martin Thermo safety shield, which acts as a safety barrier to allow timely and safe maintenance of air cannon systems. It protects workers from exposure to severe temperatures so that maintenance can take place safely and production stays on schedule.

Martin Engineering’s current ground-breaking air cannon designs are the result of the research and development in its Center for Innovation, located at the company’s headquarters in Neponset, Illinois. The center will open its doors to visitors in the summer of 2024 as part of the 50th anniversary celebrations.

To find out more about Martin air cannons and other products visit www.Martin-Eng.com.

Comments