Top Stories

Exterra rebrands to reflect expanded mineral processing platform

Exterra Carbon Solutions has rebranded as Exterra Technologies, reflecting the expanded scope of its mineral…

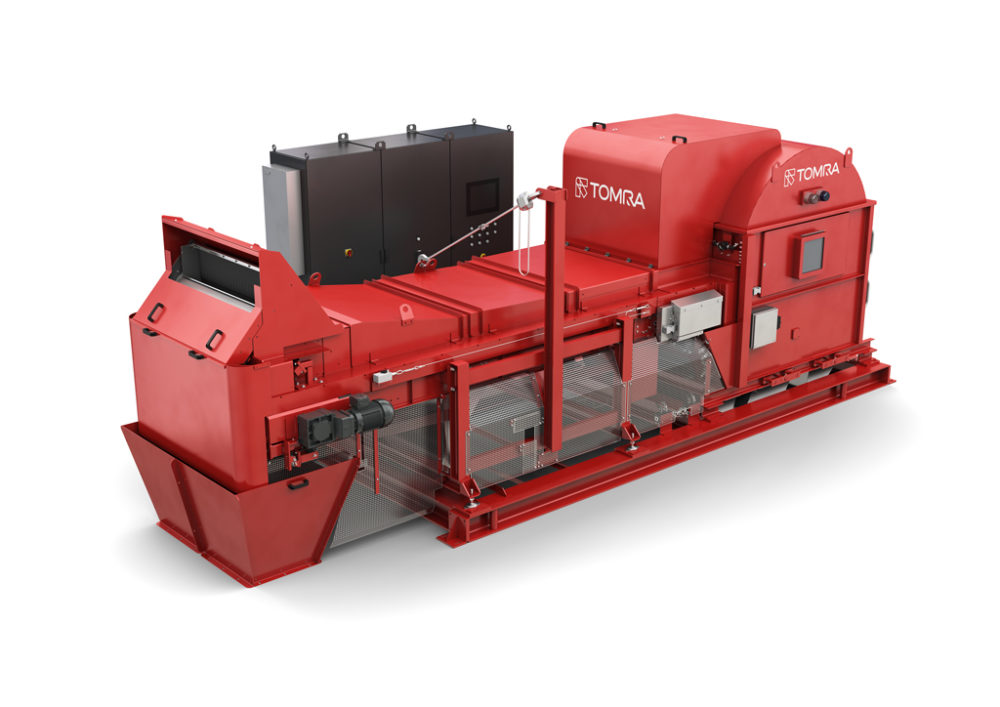

Tomra tech transforms mine waste into profit

Amid mounting pressure on global supply chains, Tomra’s advanced sensor-based sorting technology is helping mining…

Schneider Electric unveils software-defined control system

Schneider Electric has launched EcoStruxure Foxboro Software Defined Automation (SDA), the industry’s first open, software-defined…

SEEPEX launches new pump design for demanding industrial applications

SEEPEX has introduced Smart Joint Access (SJA), a new pump design aimed at improving efficiency…

Chevron lubricant doubles oil change intervals for heavy-duty transmissions

Chevron has achieved a significant milestone with its Delo TorqForce MP lubricant. Allison Transmission has…

Draslovka and Avathon form strategic alliance to automate global mining

Draslovka a.s. (Draslovka), a global innovator in sustainable chemical technologies and AI-enabled services for the…

EVP accelerates CorePlan’s global push in mining tech

CorePlan, a Western Australian technology company, announced it has secured US$3.5 million in new funding…

Global mining trends that are becoming the new normal

A new mining order: Canada and the world brace for selective megadeals and strategic repositioning in 2026

The Alaska giant: NOVAGOLD readies Donlin for its defining decade

The role of AI agents in modern mineral exploration and processing

Uranium to SMRs: Eagle Energy Metals eyes Project Manhattan 2.0 as nuclear demand surges

JV Article: Fortune Bay pushes Goldfields exploration, development amid updated economics

Exterra rebrands to reflect expanded mineral processing platform

Exterra Carbon Solutions has rebranded as Exterra Technologies, reflecting the expanded scope of its mineral…

Tomra tech transforms mine waste into profit

Amid mounting pressure on global supply chains, Tomra’s advanced sensor-based sorting technology is helping mining…

Elk Valley Resources’ expansion challenged over environmental compliance

A proposed expansion of an open pit coal mine in British Columbia is sparking fears…